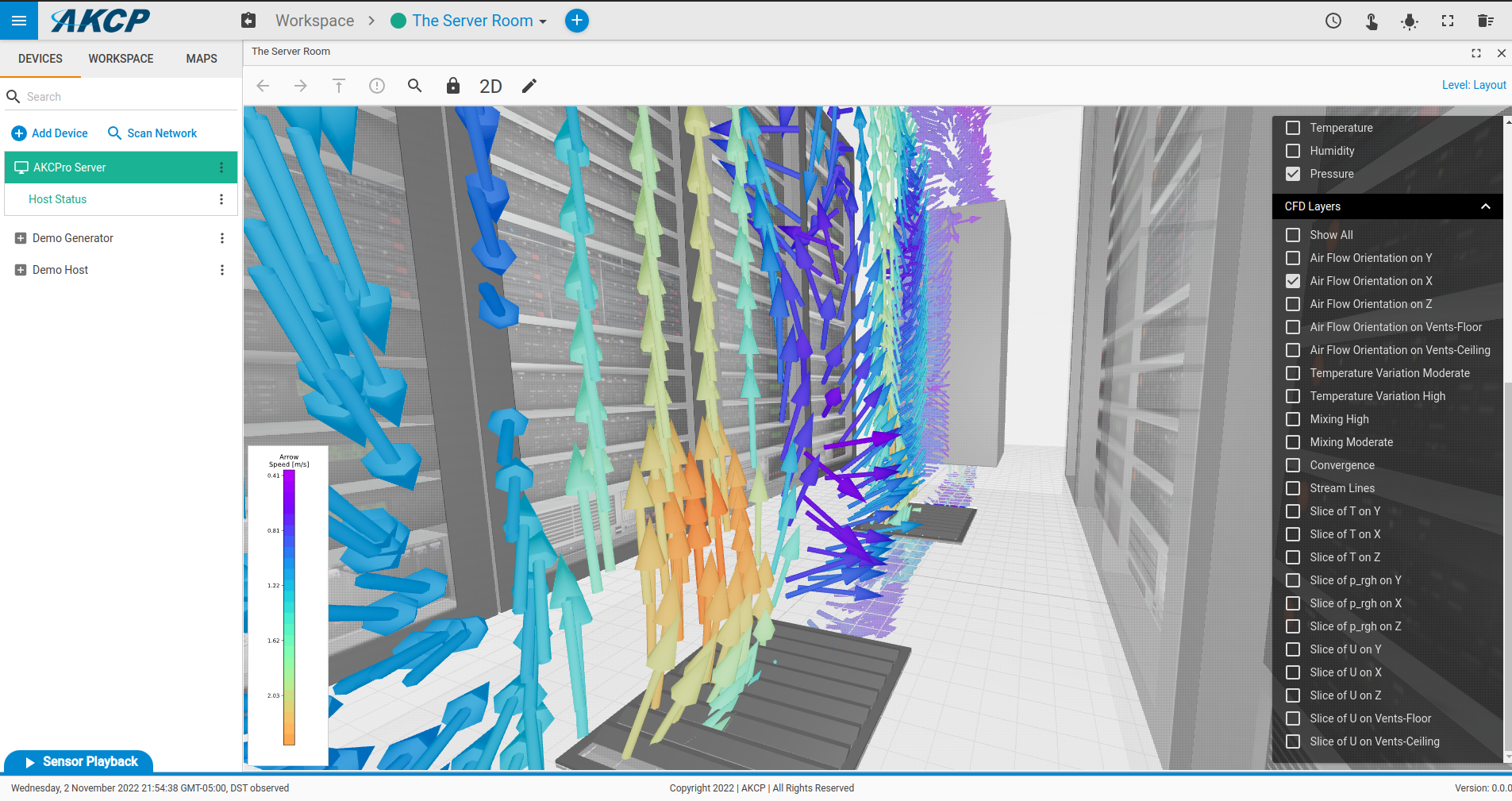

AKCP sensorCFD performs a CFD analysis of your data center, utilizing live sensor data as the input. This sensor contrained model more accurately simulates your data centers airflow, cooling capacity and efficiency.

Through the analysis of multiple sensors per rack a model of your data centers thermal capacity is generated. Identification of stranded capacity, over cooled and under utilized cooling units enables proven energy savings.

Prevent Costly Downtime

Ensuring that your rack inlet temperatures are within ASHRAE recommended guidelines prevents downtime and increases the lifespan of equipment. sensorCFD includes thermal maps which exceed the Uptime Institute recommended sensor requirements.

Win/Win for OpEx and the Environment

The reduction of energy use through efficient cooling, and effective use of cooling capacity not only saves Operationl Expenses, but results in reduced Carbon emissions. A win/win for business and the environment.

Real Time Data Center Optimization

Live sensor data means that AKCPro Server is constantly updating it’s results. As data center utilization rises and falls the sensorCFD model is updated. You have a virtual data center thermodynamics expert on hand 24/7/365

Maximize Data Center Capactiy

Reducing stranded cooling capacity unlocks the potential for higher density racks and increased server capacity without requiring additional cooling equipment to be brought online.

![]()