AKCP, the world’s oldest and largest supplier of networked wired and wireless sensor solutions announces Wireless Tunnel™ sensors for monitoring cleanroom facilities.

A cleanroom monitoring system is an essential component of any cleanroom facility. Cleanrooms such as those used in the manufacturing of sensitive electronics, pharmaceuticals require precise monitoring and control. Cleanrooms should be kept at a constant positive pressure between 5 and 20 Pascals. This ensures that outside unfiltered air does not get sucked in. Conversely in laboratories or medical facilities that are handling hazardous biological material or housing patients with infectious diseases, negative pressure should be maintained. This limits the possibility of potentially hazardous air escaping outside.

Differential air pressure sensors can also be installed on air intakes for clean rooms, checking the difference in air pressure before and after HEPA filters. Increasing pressure before the filter and decreasing pressure after the filter is an indication that the filter is not working efficiently and requires replacing.

AKCP SMT Cleanrooms are monitored with Wireless cleanroom monitoring system,

Wireless Differential Air Pressure Monitoring

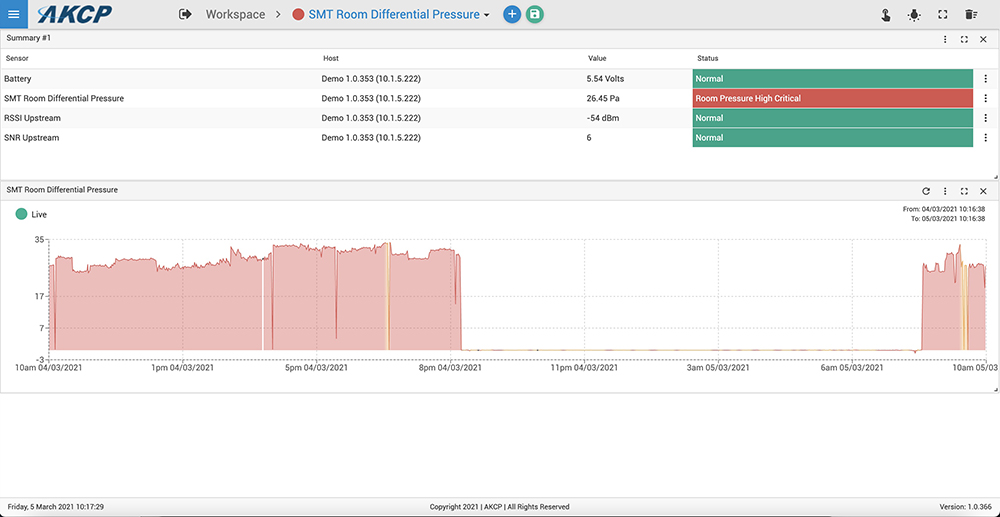

AKCP differential air pressure Wireless Tunnel Sensors deployed in cleanrooms check for correct pressure differential. The wireless, battery-powered sensor makes easy installation with a battery life of up to 10 years. A tube is connected to the outside air and the difference in pressure is calculated. User-defined thresholds for warning and critical levels are set and monitored with instant notifications when limits are exceeded.

Graph of differential air pressure for Cleanroom

Differential air pressure sensors can also be installed on air intakes for clean rooms, checking the difference in air pressure before and after HEPA filters. Increasing pressure before the filter and decreasing pressure after the filter is an indication that the filter is not working efficiently and requires replacing.

Wireless Air Quality Monitoring

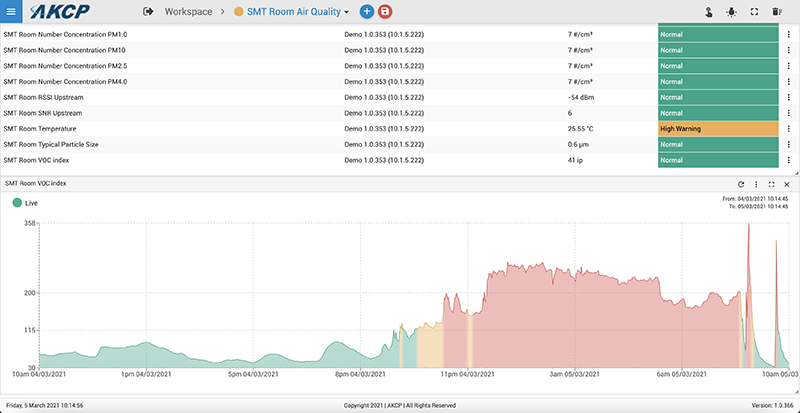

The AKCP Wireless Tunnel air quality sensor constantly monitors the quantity and size of particles in the room as well as temperature, humidity, carbon monoxide, and volatile organic compounds (VOCs).

Keeping out dust is the primary considerations in a cleanroom environment. Dust and pollen are sucked in from outside. Maintaining the positive air pressure helps prevent this, but so too does air filtration. FS209E and the ISO 14644-1 standard dictate that depending on the classification, cleanrooms should have between 10 to 600 air changes per hour. This air is filtered to keep out particles. AKCPs sensors will detect particles from 0.5 Microns up to 10 microns, displaying the number, mass, and average particle sizes.

Graph of particle sizes on intake vs. inside room

VOCs are hazardous to the health of occupants in the room. They are gaseous chemicals that originate from paints, furniture, cleaning chemicals, perfumes, and industrial processes. The AKCP air quality monitoring sensor indicates the VOC index, which signifies the rate of change per hour in the amount of VOCs in the air.

Graph of VOC index in AKCP SMT Cleanroom

The AKCP Wireless Tunnel Air Quality and Cleanroom Monitoring system are available now. Contact [email protected] for more details.

AKCP established in the USA in 1981, has 30+ years experience in professional sensor solutions. AKCP created the market for networked temperature, environmental and power monitoring in the data center. Today with over 150 employees and 200,000 installations, AKCP is the world’s oldest and largest manufacturer of networked wired and wireless sensors