The Role of Sensors and Environmental Monitoring in OSHA compliance

The Role of Sensors and Environmental Monitoring in OSHA Compliance

In today’s industrial and commercial environments, workplace safety isn’t merely a best practice—it’s a legal necessity. The Occupational Safety and Health Administration (OSHA) sets rigorous standards aimed at safeguarding employees across a wide range of industries. However, maintaining compliance can be complex, especially when relying on outdated, manual methods for monitoring environmental conditions. This is where the adoption of intelligent sensor systems and environmental monitoring technology comes into play.

Understanding the Stakes of OSHA Compliance

OSHA violations don’t just result in fines—they can lead to injuries, operational downtime, and damage to a company’s reputation. Common infractions include issues related to air quality, exposure to hazardous substances, insufficient noise control, and temperature extremes. These risks aren’t always immediately visible, which makes real-time monitoring crucial.

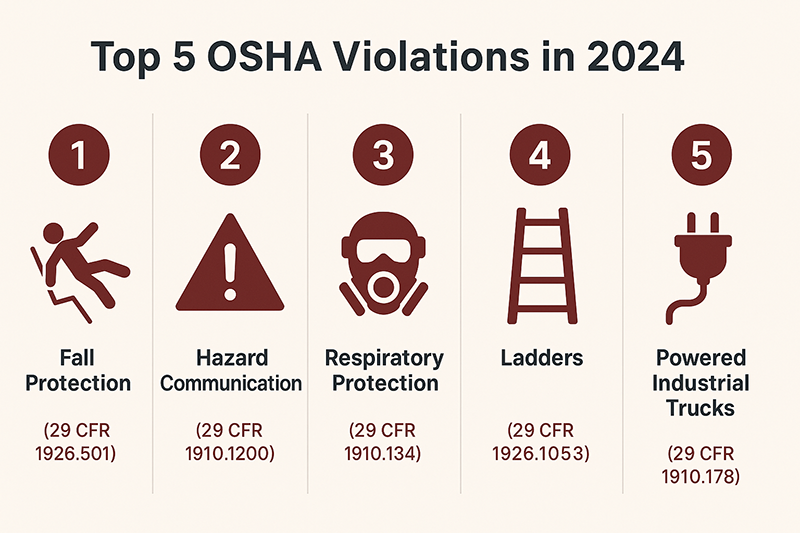

In 2024, OSHA’s most frequently cited violations remain consistent with past trends. Leading the list are fall protection failures, inadequate hazard communication, and shortcomings in respiratory protection. While some of these issues are physical and procedural in nature, many are environmental—and preventable with the right technology in place.

The Technological Shift: From Manual to Automated Monitoring

Manual logging of workplace conditions—be it air temperature, gas levels, or sound exposure—is not only time-consuming but inherently reactive. By the time a problem is discovered, it may have already affected employee health or triggered a compliance breach.

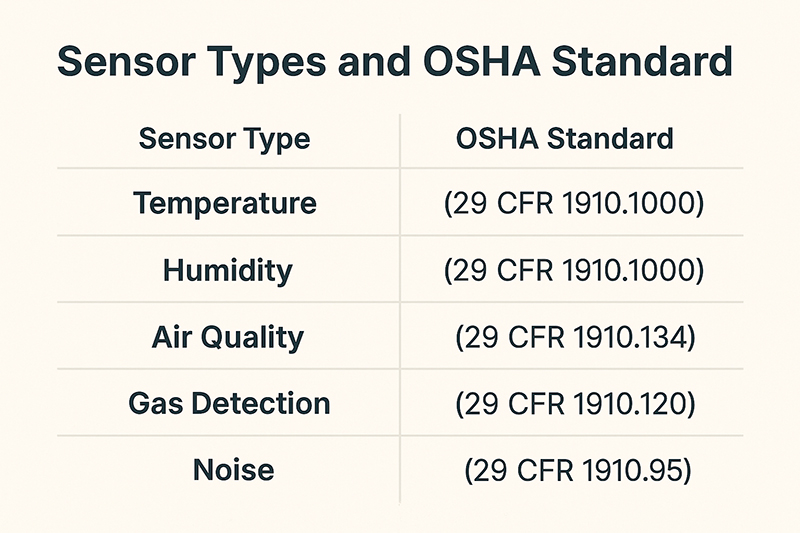

Enter IoT-driven environmental sensors. These devices automatically and continuously monitor critical parameters like temperature, humidity, noise, air quality, and water intrusion. The data is transmitted to a centralized dashboard, enabling safety managers to respond instantly when thresholds are exceeded.

AKCP’s sensor systems, for example, are designed with OSHA standards in mind. They allow businesses to track conditions in real time and generate automated reports for audits, incident investigations, and long-term safety planning.

Practical Applications Across Industries

The value of environmental sensors is best understood through real-world examples. Consider a logistics warehouse where ambient temperature plays a role in both worker comfort and equipment performance. By installing thermal sensors, the facility manager can ensure the workspace remains within OSHA’s general industry standards for safe temperatures—preventing heat stress and reducing the risk of equipment failure.

In chemical manufacturing plants, gas detection sensors offer early warnings of leaks or unsafe concentrations of airborne contaminants. This is crucial for compliance with OSHA’s regulation 29 CFR 1910.1000 on air contaminants, which sets permissible exposure limits (PELs) for hundreds of substances.

Construction sites, too, benefit from environmental monitoring. Noise sensors can be used to alert workers when sound levels approach OSHA’s limits for occupational noise exposure (29 CFR 1910.95), prompting the use of hearing protection or implementation of noise-reduction controls.

Integration and Intelligence: Beyond Compliance

Environmental monitoring systems don’t just keep companies on the right side of regulation—they also offer operational benefits. Historical data logging and trend analysis allow businesses to identify recurring risks and adjust workplace conditions accordingly. Systems like those provided by AKCP also integrate seamlessly with building management systems (BMS) or security systems for a unified safety infrastructure.

These technologies transform compliance from a reactive burden into a proactive safety culture. Workers feel more secure knowing that conditions are monitored continuously, and companies gain peace of mind from automated alerts and reporting.

Visualizing the Future of Safety

To better understand how sensor systems align with regulatory standards, consider these potential visual additions:

Infographic: Top 5 OSHA Violations in 2024

Chart: Sensor Types and Their OSHA Standard Correlates

Diagram: Example Monitoring Dashboard from AKCP IoT System

Case Study Snapshot: Before-and-After Sensor Implementation in a Factory Setting

These visuals can effectively communicate the tangible benefits and real-world impact of deploying smart monitoring solutions.

Conclusion: Safety with Certainty

OSHA compliance is not a checkbox—it’s a continuous process that demands accuracy, timeliness, and diligence. With smart environmental sensors, businesses can ensure their facilities are not only compliant but optimized for safety and performance.

AKCP’s proven technology empowers companies to detect risks early, act swiftly, and document conditions thoroughly—all of which are critical for maintaining a safe, productive, and legally sound workplace.

Interested in learning how your facility can benefit from smart environmental monitoring?

Contact AKCP for a free consultation or explore our line of OSHA-compliant sensor solutions.