A Look at Data Center Cooling Technology

Cooling a Data Center

CRAC and CRAH Differences

Recommended Temperature of a Data Center

Data Center Cooling Market Growth Projections

Misconceptions in Data Center Cooling

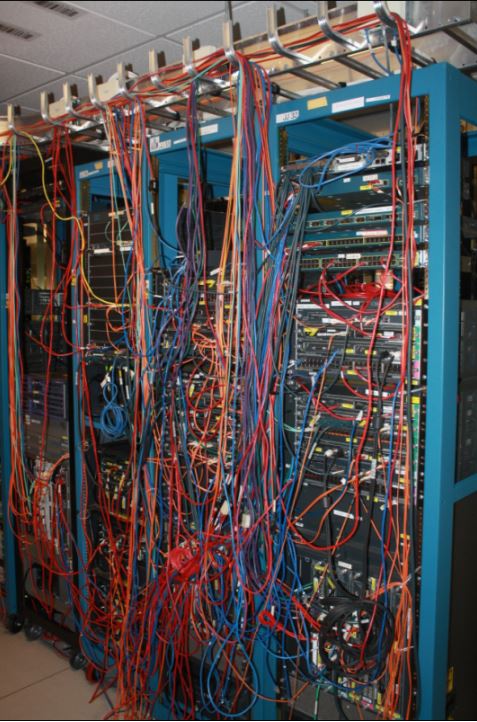

1. Bad Cabinet Layout

Not planning the arrangement of your data center cabinet is a big mistake. Arranging cabinets without a systematic design is equal to a waste of money and resources. An ideal cabinet layout should include a hot aisle and cold aisle containment design. In this design, a CRAH should be at the end of each row to gather the exhaust hot air and return it as cool air.

2. Empty Cabinet

3. Empty Spaces Between Equipment

4. Raised Floor Leaks

5. Leaks Around Cable Openings

6. Multiple Air Handlers Fighting to Control Humidity

AKCP Monitoring Solutions

To prevent hardware failure and to function at its optimal data centers must stay within ASHRAE recommended temperature and humidity ranges. Now more than ever, data center temperatures, cooling, and environmental control become much more important. If any piece of your data center cooling technology were to fail, it could result in a lot of damage within the data center. Not only that but also expensive repairs and replacements. In order to ensure that your data center cooling technology is running at its optimal capacity, monitor the temperature, humidity, and airflow,

Of course, monitoring your data center can be hard. You’ll have to check airflow both below the floor and above. The temp will shift between hot and cold spots, and humidity can change from your return airspace to the data center floor. As hard as it may be, you can’t simply leave your data center’s environment unmonitored or trust them to the single systems that control that environment. If the environmental control device and reporting device are one and the same they will fail together.

AKCP Airflow Sensor

The AKCP Pro airflow sensor is designed for systems that generate heat in the course of their operation and a steady flow of air is necessary to dissipate this heat generated. System reliability and safety could be jeopardized if this cooling airflow stops.

The Airflow sensor is placed in the path of the air stream, where the user can monitor the status of the flowing air. The airflow sensor is not a precision measuring instrument. This device is meant to measure the presence or the absence of airflow.In addition to the sensor’s ON or OFF status, the airflow sensor’s condition can also be read via an SNMP get using its OID. SNMP traps sent when critical. SNMP polling via getting available. Web browser interface available. When an alarm condition is activated the description and location of the fault can be sent via email, page.

Single Port Temperature and Humidity Sensor

In situations where both temperature and humidity can be critical, you can keep up to speed on the current conditions using this sensor. Combining temperature and humidity into one sensor frees up an additional intelligent sensor port on your base unit.

- Temperature and Humidity Monitoring on a single sensor port

- Own SNMP OID for data collection via a network

- Temperature measurement from -40ºC – +75ºC

- Relative Humidity measurement from 0% – 100%

- Powered by the base unit, no additional power needed

All you need to do is set your thresholds for low and high warning and critical parameters. The built-in graphing function of the base unit gives you a pattern of temperature or humidity trends over time.

Thermal Map Sensor

Datacenter monitoring with thermal map sensors helps identify and eliminate hotspots in your cabinets by identifying areas where temperature differential between front and rear are too high. Thermal maps consist of a string of 6 temperature sensors and an optional 2 humidity sensors. Pre-wired to be easily installed in your cabinet, they are placed at the top, middle, and bottom – front and rear of the cabinet. This configuration of sensors monitors the air intake and exhaust temperatures of your cabinet, as well as the temperature differential from the front to the rear. Use thermal map sensors to identify cabinet hot spots and problem areas.

Advantages Of Thermal Map Sensors

- Obstructions within the cabinet

- Server and cooling fan failures

- Insufficient pressure differential to pull air through the cabinet

- Power Usage Effectiveness (PUE)

sensorProbeX+

Data Center Cooling at its Best

Reference Links:

https://journal.uptimeinstitute.com/a-look-at-data-center-cooling-technologies/

https://www.digitalrealty.com/data-center-cooling

https://www.vertiv.com/en-asia/about/news-and-insights/articles/educational-articles/a-beginners-guide-to-data-center-cooling-systems/

https://datacenterfrontier.com/history-future-data-center-cooling/