Thermal Imaging

How Does It Work?

What is Thermal Imaging Used For?

How is Thermal Imaging Implemented?

Industry Applications of Thermal Imaging

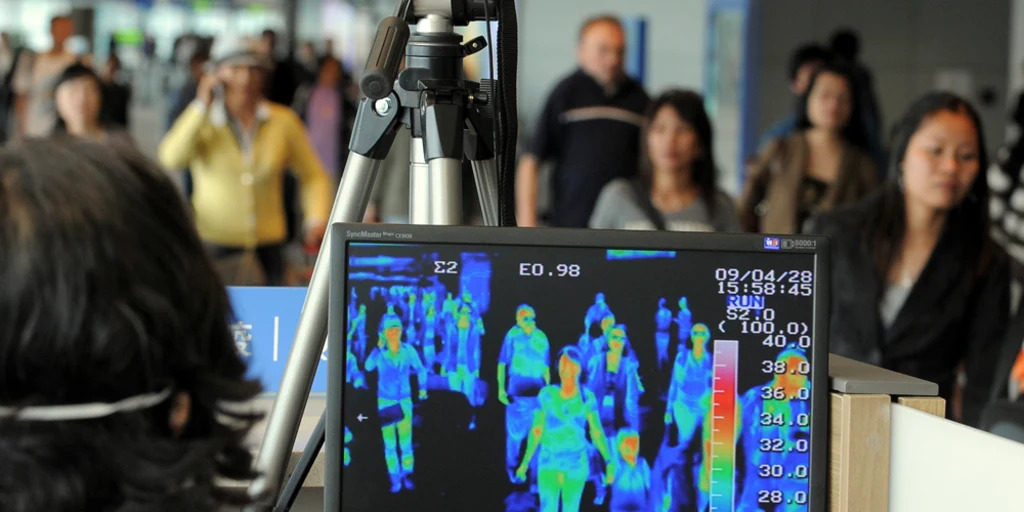

Thermal imaging is thought to have originated during the Korean War when it was employed for military purposes such as scouting and night combat missions. Since then, its applications have spread far and wide, spanning multiple fields and a wide range of practical applications.

-

Data Center

Photo Credit: arcofluidconsulting.com

The ability to identify and resolve heat-related issues in your mission-critical environment is a must and should be seriously considered in your regular maintenance schedule. This is to protect and maintain the continuous flow of information in your facility.

- Electrical Maintenance

- Plumbers

- Mechanical And Building Construction Technicians

Thermal insulation professionals employ imaging to swiftly detect leaks, which is critical for maintaining a building’s efficient temperature management. They can assess a building’s construction and detect flaws at a look. A thermal imager can readily detect heat loss from walls, HVAC equipment, doors, and windows, which are all frequent thermal performance issues.

- Animal and Pest Management

Thermal imagers have a surprising amount of applications in this discipline. They can identify probable termite activity and help spot pests or animals in dark roof regions without having to climb up into them. They’re also widely utilized to conduct wildlife surveys that are completely non-invasive and non-intrusive.

There are numerous industries that benefit greatly from the use of thermal imagers for accurate and precise visualizations of heat patterns.

Thermal Imaging In Data Centers

Infrared thermography is used to inspect electrical switchgear, uninterruptible power supply (UPS), automatic transfer switches (ATS), server systems, and cooling systems for anomalies that cannot be seen with the human eye. Early detection of abnormalities in your data center’s essential support infrastructure ensures timely remediation before costly system failures occur.

Early detection is possible with predictive maintenance, allowing you to avoid equipment failure and unplanned shutdowns, which can be costly to your business. Regular thermal imaging has numerous advantages, including:

- Find and fix hidden issues before they turn into unplanned disruptions.

- Reduce the chance of component degradation going unnoticed due to overloaded circuits or loose connections.

- Preventing equipment breakdowns and downtime results in cost savings.

Using infrared thermography on a regular basis allows you to compile a thorough history of your equipment and ensures the resiliency of your critical facility infrastructure.

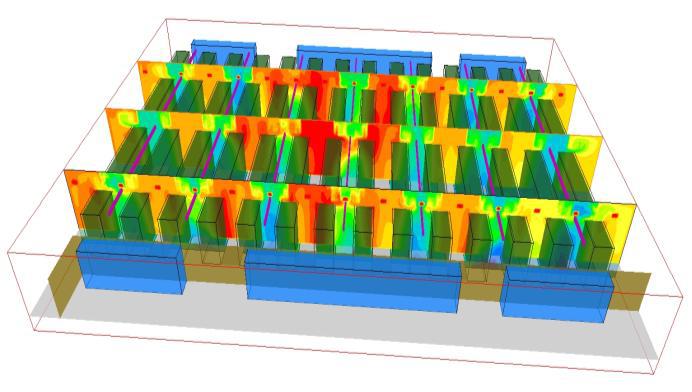

Identifying Hot Spots in Data Centers with Thermal Imaging

Photo Credit: www.vertiv.com

Thermal imaging can help uncover mechanical faults such as hot spots in addition to identifying irregularities in electrical devices. A thorough investigation can reveal regions where high heat could jeopardize data center network resilience. This will allow you to develop solutions that will both assist you to fix the problem and lower your operational costs.

Temperature plays a crucial part in keeping a data center stable and efficient. Maintaining the life span and performance of your server racks and network equipment requires keeping them at safe operating temperatures.

Monitoring With AKCP

Airflow and Thermal Mapping for IT Cabinets

The Cabinet Analysis Sensor (CAS) features a cabinet thermal map for detecting hot spots and a differential pressure sensor for analysis of airflow. Monitor up to 16 cabinets from a single IP address with the sensorProbeX+ base units. The Wireless Cabinet Analysis Sensor is also available using our Wireless Tunnel™ Technology.

Differential Temperature (△T)

Cabinet thermal maps consist of 2 strings of 3x Temp and 1x Hum sensor. Monitor the temperature at the front and rear of the cabinet, top, middle, and bottom. The △T value, front to rear temperature differential is calculated and displayed with animated arrows in AKCPro Server cabinet rack map views.

Differential Pressure (△D)

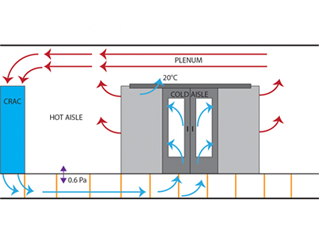

There should always be a positive pressure at the front of the cabinet, to ensure that air from hot and cold aisles is not mixing. Air travels from areas of high pressure to low pressure, it is imperative for efficient cooling to check that there is higher pressure at the front of the cabinet and lower pressure at the rear.

Rack Maps and Containment Views

With an L-DCIM or PC with AKCPro Server installed, dedicated rack maps displaying Cabinet Analysis Sensor data can be configured to give a visual representation of each rack in your data center. If you are running a hot/cold aisle containment, then containment views can also be configured to give a sectional view of your racks and containment aisles.

AKCP Cameras For Optimal Visual Security

Pan Tilt Dome Digital Camera

The securityProbe AKCP Pan Tilt Dome Digital Camera is designed to provide the securityProbe line of devices further capabilities. You can not only remotely monitor assets and infrastructure, but you can also see any concerns by integrating the AKCP PTDC Camera with a securityProbe from anywhere in the world.

High-Resolution Pan Tilt Dome Camera

High-Resolution IR Digital Camera

The AKCP High-Resolution Pan Tilt Dome Digital Camera is designed to provide the securityProbe 5ESV and Door Control Unit devices with more functionality. You can not only remotely monitor assets and infrastructure, but you can also see any problems by pairing the AKCP HD-PTDC Camera with a securityProbe 5ESV from anywhere in the world.

Universal Mount Digital Camera

Use this Universal Mount Digital Camera (UMDC) digital camera to visually inspect your enterprise assets and resources via your browser from anywhere in the world. The AKCP UMDC provides optimum features for deployment with the AKCP securityProbe series. It has IR night vision capability and delivers between 15fps and 30fps depending on the resolution selected.