AKCP Concrete Temperature Sensors

The strength of a concrete structure relies on the quality of the concrete used. Concrete quality can be compromised due to temperature, especially during extreme weather conditions.

The hydration reaction rate of concrete depends on the temperature. As temperature increases, the reaction also increases. This means that concrete kept at a higher temperature will get stronger faster. However, its final strength will be lower. This is because the physical form of hardened cement paste is less structured when hydration proceeds at a quicker rate. The temperature has a detrimental impact on the strength of the concrete. This suggests consistent monitoring of the temperature to ensure a strong and durable structure.

Concrete Temperature Limit

Appropriate temperature is important for concrete to set and cure properly. Various standards set a limit to the concrete temperature. This is to ensure the outcome of a high-quality concrete structure with specified requirements. These standards require strict compliance of the contractors. By following, they can bring off the desired structural strength and longevity.

Higher concrete temperature requires more water content to achieve the required slump. Having it said, more water can result in greater shrinkage and lower air content at a given air-entraining admixture. Additionally, the weather is also a threat as mentioned. A combination of both high-temperature concrete and ambient temperature will reduce set time. This can result in a durability problem and thermal cracking. While low-temperature concrete setting in cold weather also introduces negative impacts. If fresh concrete freezes, it will also influence the rate of strength, reducing it up to 50%.

-

Temperature Limit during Hot Weather

According to ACI 301.5, ACI 301, and ASTM C94, there is no temperature limit set on fresh concrete during hot weather. Provided that they took the precautionary measures in proportioning, production, delivery, placing, and curing concrete. Nonetheless, a temperature limit between 26.7°C and 35°C is set by the ASTM C 1064-86. This is subject to adjustment based on the project’s specifications. AS 1379 requires a temperature within the range of 5°C to 35°C at the point of delivery during hot weather conditions. If the temperature goes beyond 35 degrees C, use ice-cold water to prevent damages such as cracking.

-

Temperature Limit during Cold Weather

For cold weather conditions, ACI 306 also sets limits for concrete temperature. The concrete temperature as placed shall be 12.77°C to 4.44°C, depending on the structural dimension. Smaller dimensions have a higher minimum temperature limit. This accounts for less heat that can be retained. Placing concrete at a temperature below 4.5°C requires a higher temperature. It is also important to prevent freezing of concrete 24 hours after placement. This lets the concrete obtain the optimal strength. The same action goes with the assumption of freezing temperature after placing the concrete. However, it should be noted that after heating concrete, it must prevent sudden cooling. This circumstance can cause damage, such as thermal cracking.

The Benefit of Concrete Temperature Monitoring

Analyzing the concrete mixture is the key to a strong structure. Concrete that has inappropriate temperature and setting may have a hard time solidifying. This will sacrifice not only the quality of the structure but also the safety of the people.

Photo Credit: forconstructionpros.com

Monitoring the concrete temperature will provide useful data about the curing process. Performing this critical step will eradicate complications. Examples are overheating of the concrete, which usually happens on mass concrete. It can also help avoid a large temperature gradient. This can result in possible cracks on the structure after completing it. The temperature gradient is the difference between the inner core and surface of the concrete. Chlorides and other liquids can enter these cracks damaging the reinforcing steel.

An additional benefit of concrete temperature monitoring is the data that followed the curing process or maturity of the concrete. The temperature data can be used in determining accurate concrete strength.

Concrete temperature monitoring also saves time. The efficiency of the system follows the concrete maturity process. Decision-making in the continuity of the construction can be easily done using the monitoring data. The concrete temperature monitoring optimizes project schedules and prevents delays in construction operations.

Most importantly, monitoring the temperature of the concrete will ensure the safety of the people. Appropriate temperature mitigates risks like a structural failure. The construction workers and the people utilizing the structure will be safe from such accidents.

Concrete Temperature Sensors

To be able to control the heating or freezing of concrete, monitor the process is needed. This can be done using concrete temperature sensors which will guide in maintaining the concrete temperature threshold. From the preparation of the concrete mix, up to the maturity process. They are capable of working in extreme conditions and can hold up temperature values up to 170°F.

Temperature sensors use a reader in collecting data. Data can be accessed with a wired connection for traditional sensors. For modern sensors, it is through wireless technology. The data is easier to know how well the concrete is curing. This allows the contractors to make faster and more informed decision-making whether it is safe to open the formwork or to shore in a project.

Just like other sensors, placement of concrete temperature data is critical. They should be placed on appropriate locations and key structural components. This makes them effective in reading accurate data. A thermal control plan will identify the best locations for the temperature sensors. In general, temperature monitoring sensors are usually installed at the concrete’s hottest location and few inches below the nearest surface from the hottest location.

Ideal Sensor for Concrete Temperature

When it comes to the choice of temperature sensors, contractors have more selections. They can choose based on cost, accuracy, ease of use, and how they fit their project’s specifications.

Wireless Temperature Sensor

The two most commonly used are wired or thermocouple and wireless sensors. The thermocouple is an inexpensive solution and widely available. However, wireless sensors have the benefit of ease of use. The wireless sensor allows flexible and remote monitoring where the data is accessible on any mobile device.

Wireless sensors are also embedded in the concrete. They are placed usually on the rebar, to increase the wireless signal range. The recorded data can be accessed by downloading it using different wire-free communication protocols. Examples are Bluetooth LE, LoRa, Zigbee, or Wi-Fi. Unlike cabled systems, they have little risk of damage on the construction site after pouring. The wireless sensor is secured, so there will be no interruption in data transfer. Furthermore, its installation process is faster and simpler as there is no need to extend wires out of the concrete.

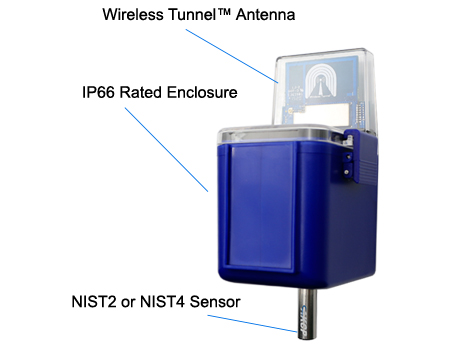

AKCP Wireless Temperature Sensor

Increasing longevity and minimizing damages are the goals of every mass placement project. Temperature plays a critical role in achieving these two. Temperature monitoring is important to systematically track the process of curing concrete and ensure a finished structure’s quality. Isn’t it good to think that the structure will still stand strong for the years to come?

A more convenient data accuracy should not be a challenge. AKCP wireless sensors help contractors in monitoring the concrete temperature. Conveniently acquiring data on or off-site without compromising accuracy.

AKCP Wireless Sensor works with a built-in calibration check in a single stainless steel tube. Working as a pair, they check each other’s values once a second for accuracy. If the sensors detect temperature are out of allowable thresholds, an alert is sent warning that the sensor requires re-calibration.

- 4x AA Battery powered, with 10 -year life.

- USB 5VDC external power.

- 12VDC external power.

- Custom sensor cable length up to 15ft to position sensor in an optimal location.

- NIST2 dual-sensor calibration integrity check.

- NIST3 triple sensor calibration integrity checks with failover.

Do not let a single mistake be a catastrophe. Message AKCP now!

Reference Links:

https://theconstructor.org/concrete/concrete-temperature-limit/25863/

https://maturix.com/knowledge-center/why-use-thermocouples/

https://www.constructionjunkie.com/blog/2020/7/16/the-best-concrete-sensor-in-2020