Generator Monitoring and Alerts

“Power when you need it” Remote generator monitoring system and alerts ensure your backup power systems are always at the ready when called upon.

What Is A Remote Generator Monitoring System?

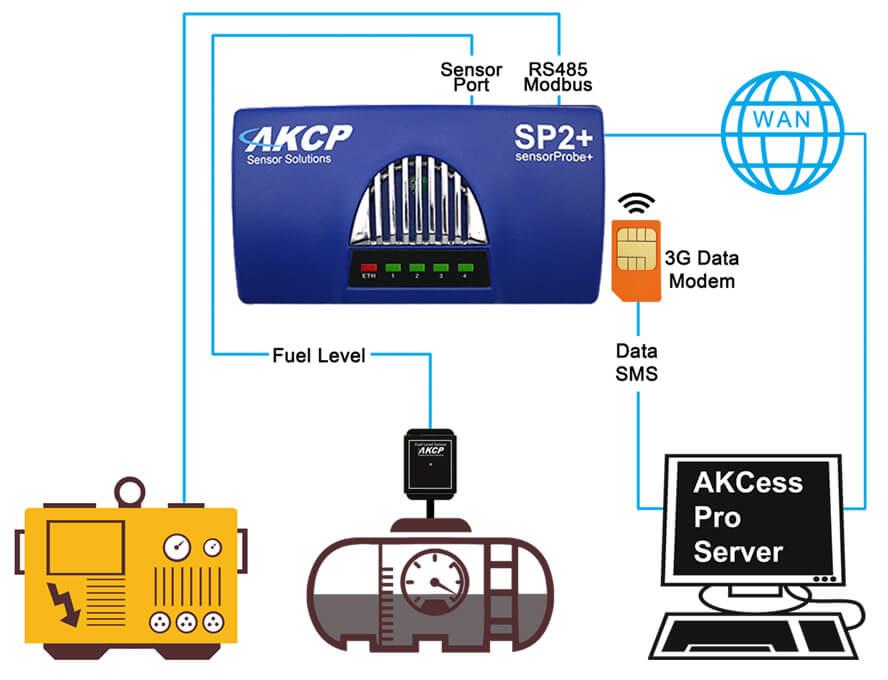

A device that connects to your generator and via supplied sensors, or utilizing sensors already installed on the generator, monitors the status and health. Communication between the generator and the monitoring system is typically over the Modbus RS485 connection to the generator control panel. Most popular control panels such as ComAp and Deepsea come with an option for Modbus RS485. Some control panels with an Ethernet TCP/IP network can be monitored via SNMP to collect data.

When these communications aren’t available, control panels will typically have dry contact alarm outputs that can be programmed for specific alarms. These are only alarm outputs, not actual readings of engine speed, fuel level, and temperatures.

Additional sensors can be added if the above options aren’t available. For example, a battery health monitoring sensor can check the engine battery and ensure that it’s properly charged, outputting the correct voltage and current. Fuel level sensors are installed on reserve tanks and power meters on the generator output. These sensors connect to a base unit that contains the communications and stores the data.

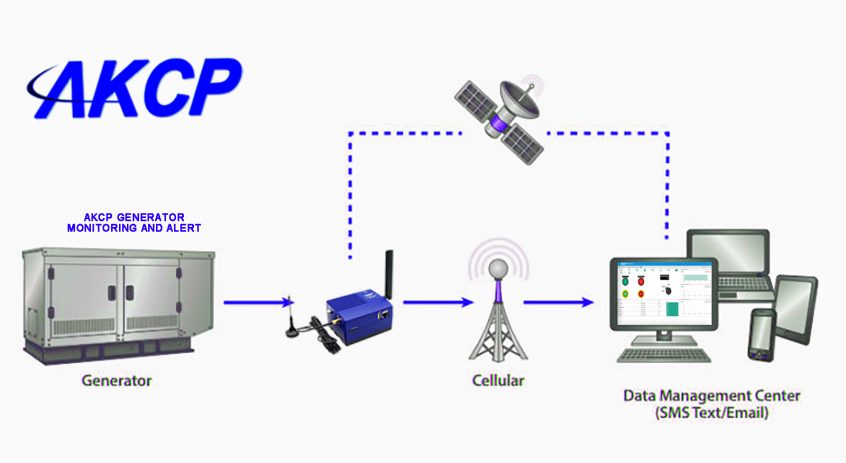

The remote generator monitoring system collects the data from the sensors and connects to the internet. This provides remote monitoring over WiFi, cellular network, or wired ethernet, depending on what is available. These wireless protocols provide the main communications for remote monitoring of the system.

For generators installed in difficult locations with no network, LoRa based wireless sensors can be installed, and communicate the generator data over a long distance to the base unit installed at a suitable location with online communications available.

What Can I Monitor And Why?

There are multiple parameters that you can monitor with a remote generator monitoring system. It’s like having a technician onsite 24/7, always checking that the generator is in good health and running condition. Alerts through e-mail and SMS are sent to warn when generator parameters are outside of normal bounds. Reporting these critical conditions to reduce downtime and maintenance costs. For standby power systems, faults can be detected and alerted to reduce incidents of failure to start.

When connecting through Modbus RS485 or SNMP, there are many parameters that can be monitored. These often are dependent on the specific engine and the control panel. Typically the following can be monitored:

- Engine Speed

- Oil Pressure

- Engine Temperature

- Power Output

- Engine Runtime

- Fuel Flow

- Voltage

- Frequency

These parameters have thresholds set based on the generator manufacturers’ recommended limits, and when exceeded alarms are sent. Some remote generator monitoring systems have a control aspect as well and are able to remotely start and shut down the generator if critical faults are detected.

Dry contact alarm outputs on the control panels typically include:

- Failure to Start

- Engine Overspeed

- Oil Pressure Alarm

- Low Fuel Alarm

Most modern generators have error codes that are used to identify specific problems that the engine control unit (ECU) has detected. These error codes can be communicated over SNMP or Modus RS485, and then referred to the manufacturer for advice.

Generators require servicing at regular intervals, based on the number of runtime hours. A remote generator monitoring system can check the runtime hours and send advance warnings when maintenance such as change of oil, filters, and cleaning is required.

Generator Monitoring Systems are available from AKCP for all types of generators. With a wide range of sensors and base units. AKCP offers both wired and wireless options for remote generator monitoring. Optional Cellular data communications and GPS for locating your generator in AKCPro Server centralized monitoring software. If you have specific requirements or questions please contact us at sa***@ak**.com