All You Need To Know About Medical-Grade Refrigeration Units For Pharmaceutical Storage And Transport

One of the pillars for a successful healthcare system is the stable maintenance of vaccines, medications, reagents, and patient samples. These tend to be time- and temperature-sensitive. Vaccines and medicines are transferred through a cold chain from creation up to the time it is administered to the patient.

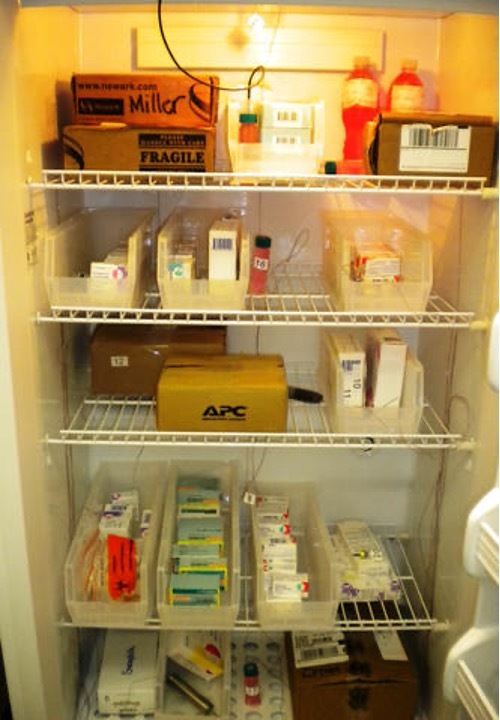

Standard fridges do not suffice in storing medicine and vaccines. They should be kept in specialized medical refrigerators. These medical refrigerators are made with robust materials that are more durable and are less likely to fail. Temperature controls are also more accurate compared to ordinary household ones. They are equipped with alarms that send alerts when a door is left open or if there is a rise or fall in temperature. Grated shelves are used within to allow better airflow and maintain more consistent temperatures. Aside from being used in the healthcare industry, such as in hospitals, clinics, research laboratories, surgery centers, and physician offices, they can also be used in crime labs.

Different types of refrigeration storage units

Purpose-built/Pharmaceutical-grade/Medical-grade Storage Unit

These are units specifically manufactured for healthcare storage, including clinical products, vaccines, and other biologics. Medical grade units are manufactured with forced air refrigeration, which allows for air to thoroughly circulate inside the unit in order to create a uniform atmosphere, regardless of a top shelf or a bottom shelf location.

Stand-alone Storage Unit

This unit does not depend on any other system or device to exercise its desired function, operation as an independent storage unit. An example of this is when a freezer is used as a freezer only, and a refrigerator is used as a refrigerator exclusively.

Household-grade Storage Unit

A storage unit is intended to be sold for home use. Most often than not, these refrigerators are not able to meet temperature uniformity standards, which may cause some parts of the unit unfit for cold storage.

Dormitory-style (Bar-style) storage unit

This unit is composed of a refrigerator and a freezer with an evaporator plate (cooling coil) and one exterior door. The cooling coil is often found inside the icemaker compartment (freezer). However, these units tend to pose a risk of freezing vaccines, even when used as temporary storage, as they are not designed for temperature stability.

Importance of using a medical-grade fridge

Accurate temperature regulation

Many vaccines and medicines are required to be kept at a temperature range between 2°C and 8°C (35°F and 46°F) in order to maintain the cold chain during storage and transportation.

Medical grade refrigerators are often equipped with the latest high-tech thermometers in order to monitor and record the temperature inside the vaccine and the fridge unit. Standard fridges are not able to provide the same kind of temperature regulation, and their thermometers do not show the same level of accuracy.

Medical-grade freezer and refrigerators are capable of maintaining superior temperature stability. Fewer deviations and significant, rapid changes in temperature are recorded.

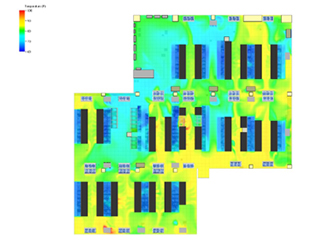

They also have the capacity to retain uniformity in the temperature throughout all areas of the cabinet. Temperature uniformity eradicates hot and cold spots that places contents at risk of temperature deviation. Uniformity depends on storage application, but legitimate medical-grade refrigerators will be able to meet stringent uniformity requirements of +/-1°C.

Medical-grade storage units also have the ability to restore the unit to the set point despite regular door openings or temperature recovery. Faster recovery keeps items at the right temperature during regular use of the units.

Temperature monitoring

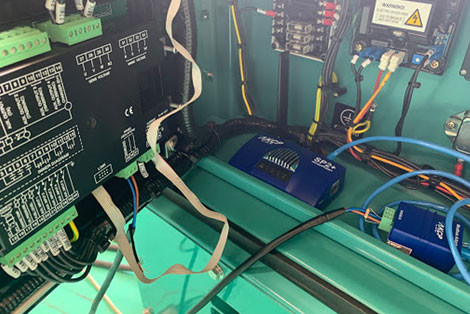

Since keeping temperatures at a constant level is essential for medications, vaccines, patient samples or reagents is important in ensuring a patient’s safety, it is crucial to have an accurate temperature monitoring scheme. Medical-grade refrigerators possess microprocessor temperature controllers and digital displays for accurate temperature regulation. Companies like AKCP also provide NIST traceable, calibrated temperature monitoring systems for medical refrigerators.

Temperature excursion alarms

Medical grade refrigerators are equipped with alarms that sound whenever there’s a temperature excursion, power failure, or ajar door. This is important to maintain the integrity of the vaccines and reduce spoilage. Some manufacturers integrate software that allows for displaying historical temperature data, interactive temperature graphs, and event log. These systems also have the capability to input minimum and maximum temperatures needed in a specific period to ensure regulation.

In order to track temperature history in case of a power loss, some medical-grade refrigerators have back-up battery systems in place that can continue monitoring data. Should healthcare facilities use third-party monitoring solutions, some medical-grade refrigerators and freezers have been manufactured to accommodate this type of installation. Depending on the setup, options can include special ports to permit independent temperature probes to be easily placed within the unit.

The alarms immediately notify healthcare staff, which allows them to take action in case of a temperature excursion. In some rare instances, it is possible for the cold chain to be broken and for the vaccines to remain safe to use; however, it is always highly advisable for such a situation to be avoided. A 2019 study estimated that 25% of vaccines are degraded by the time it reaches the demand point. A vaccine is often discarded when it is exposed to temperatures outside the specified range. Due to temperature mistakes in the cold chain, around US$34.1 billion is lost annually.

Tighter security

Medicines and vaccines can be subject to theft due to their expensive and in-demand nature. Due to this, medical-grade refrigerators often have security features like keyed locks in order to prevent unwanted tampering. Other refrigerators have electronic access security features that use passwords or pins to regulate and track access.

These safety measures do not only prevent theft, but they also ensure that the medical fridges are not accidentally opened by a cold chain staff before its intended purpose.

Glass door or solid door

Medical grade refrigerators can come with glass or solid doors.

Glass door medical fridges allow healthcare practitioners to view the content of the fridge and determine the current stock of vaccines and medicines. Due to this, the contents would not be opened as regularly, which aids in maintaining the required temperature range.

A solid door serves as an added layer of security, so unnecessary personnel would not be able to see what is inside.

FDA approval and other certifications

FDA Registered suppliers of medical-grade refrigerators are required to comply with a specific set of high standards compared to other suppliers. SO 13485 (Quality Management System for Medical Devices) requires suppliers to abide by strict regulation regarding product testing and validation, design controls, and post-market observance.

ISO 13485 serves as a guide to ensure that design, manufacture, and support of refrigerators at a quality aligned with the needs of clinical applications. Suppliers must also comply with 21 CFR Part 820 (FDA quality system regulation), which requires regular FDA audits, governance, and accountability measures to maintain consistent quality of equipment and post-sales process.

It is also essential for suppliers to procure Certificates of Calibration to prove that the cold storage unit being offered has been calibrated with a measuring device that is compliant with NIST ISO 17025.

Custom options and high-quality body construction

There are multiple sizes of medical-grade cold storage equipment offered in the market, but refrigeration units can also be customized depending on the storage need of the client, such as the type, location of drawers, shelves, and baskets.

The right storage equipment is crucial in reducing errors and ensuring patient safety. A conducive setup of the unit allows easy removal and loading of the contents in the refrigerators by healthcare professionals. These shelves and drawers are also designed to enable necessary airflow.

High-quality construction is needed for all medical equipment. The use of stainless steel and other materials produced for routine disinfecting such as FDA and EPA registered anti-microbial powder is necessary to ensure the refrigerators are suitable for medical laboratories.

Improper refrigerator repercussions

The use of improper refrigerators for clinical cold storage may put patients at risk by being administered a degraded vaccine due to improper temperature control. Vaccines and medicines are expensive commodities, and the use of low-quality refrigerators for their storage can cause a huge financial loss due to compromised products that would require disposal.

Since patient samples are stored in medical-grade refrigerators, keeping them in improper refrigerators may result in the loss of irreplaceable patient samples that are crucial for lab testing and research success.

Ultimately, the improper use of refrigerators can cause disruptions to the entire workflow. Due to the grave repercussions of unreliable refrigeration, healthcare professionals seek compatible medical-grade refrigerators to increase productivity and reduce the overall risk in the cold chain.

Despite having costly initial acquisition prices to procure medical-grade refrigerators, the investment of purchasing a unit is worth it in the long run. Legitimate and high-quality medical-grade refrigeration units ensure reliability and quality that mitigates the risk of substantial financial loss due to improper storage. It will also limit the need for frequent acquisition of units for replacement, paving the way for long-term savings.

Sources

https://www.helmerinc.com/what-is-a-medical-grade-refrigerator

https://www.coolmed.co.uk/knowledge/what-is-a-medical-grade-refrigerator