When it comes to handling temperature-sensitive, high-value equipment, assets, or perishable goods, there’s a lot on the line. A remote temperature monitoring system is essential for a variety of applications, including maintaining ideal temperatures and humidity levels. Temperature monitors have a wide range of uses; they’re even employed in geotechnical monitoring. A temperature sensor is used to calculate how cold or hot a region is and convert it into a readable measurement from a bird’s eye perspective.

What is a Temperature Monitoring System?

What Does It Do?

How Does It Work?

-

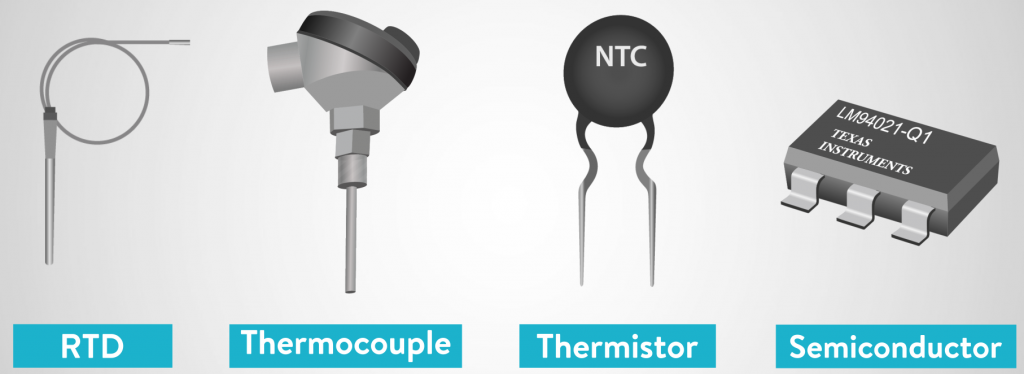

Certain temperature sensors must be in direct touch with the item or person in order to measure temperature changes or decreases. These sensors are used to detect gases, solids, and liquids that have a broad range of temperature fluctuations. The spectrum includes the Resistance Temperature Detector (RTD), Thermocouple, Thermistor, and Thermometer.

-

Sensors that do not come into direct touch with the item to detect temperature are known as non-contact temperature sensors. Radiation released by the source of energy is used to determine the degree of hot and cold. The most common forms of non-contact temperature sensors are thermal imaging and infrared sensors.

Things To Consider While Choosing The Right Temperature Monitoring System

-

Sensing Environmental Alarms

-

Water Damage

Photo Credit: iwa-network.org

Water leaks have an impact on our everyday life and can cause the temperature sensor to malfunction. If there is water near the equipment, you must be informed. As a result, if you select the right sensor, you will be notified if water is accumulating, allowing you to avoid excessive harm. -

Humidity

Excessive moisture in the air may wreak havoc. It can create corrosion or degradation in the equipment, which can lead to a short circuit. Humidity levels that are too high or too low might harm equipment; thus, it is better to use a temperature sensor that alerts you to the quantity of humidity – to avoid damage to the equipment. -

Airflow

Airflow disruptions are frequently the source of serious effects. If you have airflow sensors installed, they will alert you if an airflow pressure exists that might harm the device.

-

Integrated Support

Photo Credit: www.marineinsight.com

What Do I Need for My Temperature Monitoring System?

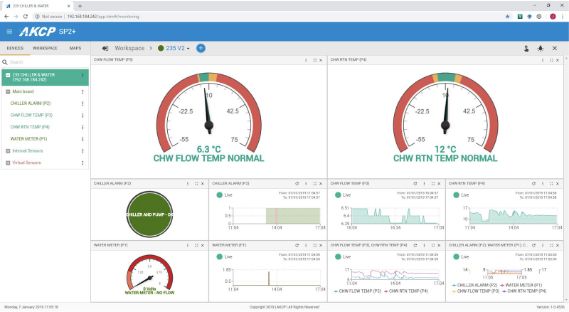

Words like “protocol” and “alarm output” may make you nervous when thinking about remote monitoring; but, unlike direct monitoring of equipment alarms, site temperature is one of the easiest things to keep an eye on from afar.

One or more temperature sensors and a remote terminal unit (RTU) to send the temperature sensor alerts back to you are all you need for this type of monitoring. You may utilize an alarm master station to transmit warnings through text, email, or any other manner if you have a medium or big network.

Practical Temperature-Monitoring Sensors

Electronic equipment generates a lot of heat by nature. Thermal shutdowns will occur sooner or later if this heat is not appropriately monitored with temperature sensors.

Temperature sensors installed at the sites will help you avoid service interruptions and equipment damage. These sensors are inexpensive, straightforward, and small.

Where Do I Find A High-Quality Temperature Monitoring Solution?

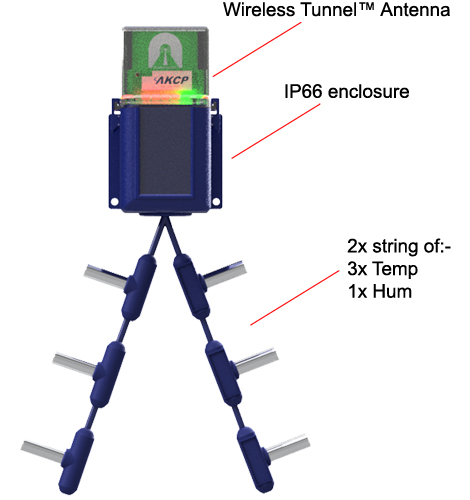

Wireless sensors are easier and cheaper to place. Therefore, being the more flexible choice as opposed to wired sensors. They can be of particular use to data centers that are not yet at full capacity. When using wireless sensors, new sensors can be added along with equipment racks. Wireless sensors also allow for the sensor networks to immediately adapt to layout changes without rewiring.

In checking wireless sensors, it is best to give attention to sensor functionality, battery capabilities, and security.

WIRELESS CABINET THERMAL ANALYSIS SENSOR

Wireless Thermal Mapping of IT Cabinets

Wireless thermal mapping of your IT cabinets. With 3x Temperature sensors at the front and 3x at the rear, it monitors airflow intake and exhaust temperatures, as well as provides the temperature differential between the front and rear of the cabinet (ΔT) Wireless Thermal maps work with all Wireless Tunnel™ Gateways.

Thermal Maps are integrated with AKCPro Server DCIM software in our cabinet rack map view. For more details on the cabinet, thermal map sensors view here.

Single Port Temperature and Humidity Sensor

SINGLE PORT TEMPERATURE AND HUMIDITY SENSOR

When you need to know the temperature of a room, enclosure, or cabinet this sensor can be used. Housed in a thermally conductive metal tube it is accurate and quick to react to changes in temperature. The sensor can be easily mounted with screws, adhesive, or optional DIN rail clips making it ideal to scatter around the facility as well. Combining temperature and humidity into one sensor frees up an additional intelligent sensor port on your base unit. Thresholds can be set for low and high warning and critical parameters. The built-in graphing function of the base unit gives you a pattern of temperature or humidity trends over time.