Remote Generator Monitoring

A generator is like any other engine, it needs maintenance. Unlike a car, however, you are not always looking at the various gauges and indicators. Generators all too often are set up and left, and you only know it’s broken when you need it the most! Generators in remote locations are even more critical to monitor and ensure they are always ready to supply backup power whenever called upon.

Monitoring Solutions

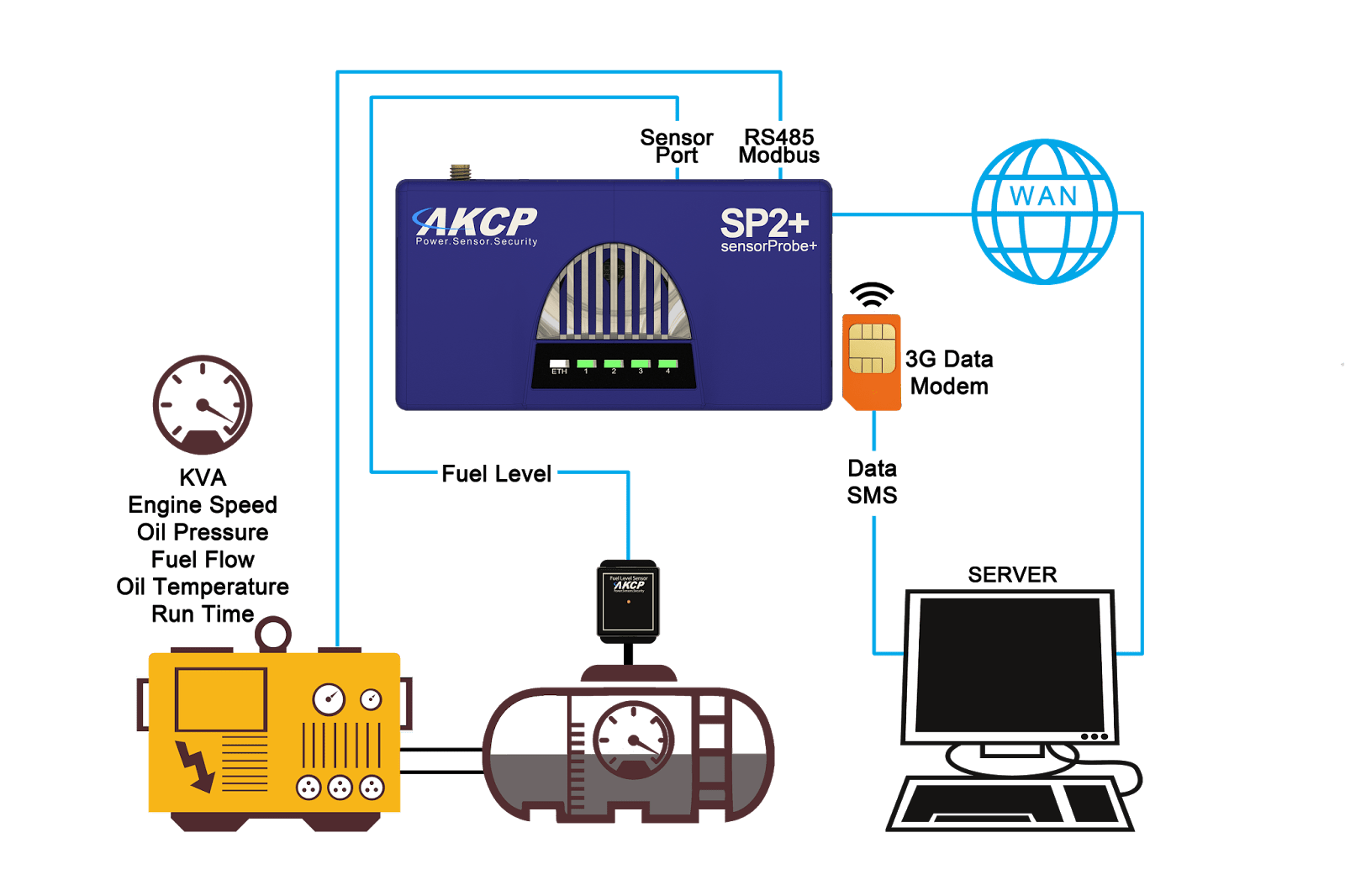

You can take a lot of the worry and management overhead of this situation away by implementing monitoring solutions that will alert you when maintenance is due, or something just not quite right. Most generators come with an engine control panel, these usually have some kind of output, probably Modbus RS485 or CANbus. By referring to the manufacturers manual you can find the specific Modbus register addresses for monitoring engine parameters. Common parameters you may want to measure are the oil pressure, oil level, water temperature, engine speed, runtime, fuel flow and output. Many generators give access to a lot more data than this if you require it.

By connecting a monitoring system to the output, you can read these values, and remotely access the data over the internet. Thresholds for specific parameters can also be set so you will be alerted when oil pressure is too high, or oil level too low. This will allow you to be pro-active in your maintenance, and ensure that your generator is always ready to go.

Alerts from these systems can be sent in the form of E-mail, SMS, SNMP traps and so on. Most systems have an ethernet port for network connection, and some also include cellular data modems, which simply require you to install a SIM card and you can receive alerts directly from the device itself.

Notifications can also be sent when the engine runtime hours have reached certain milestones to remind you of preventative maintenance schedules such as oil changes, air filter cleaning and so on.

AKCP Generator Monitoring System

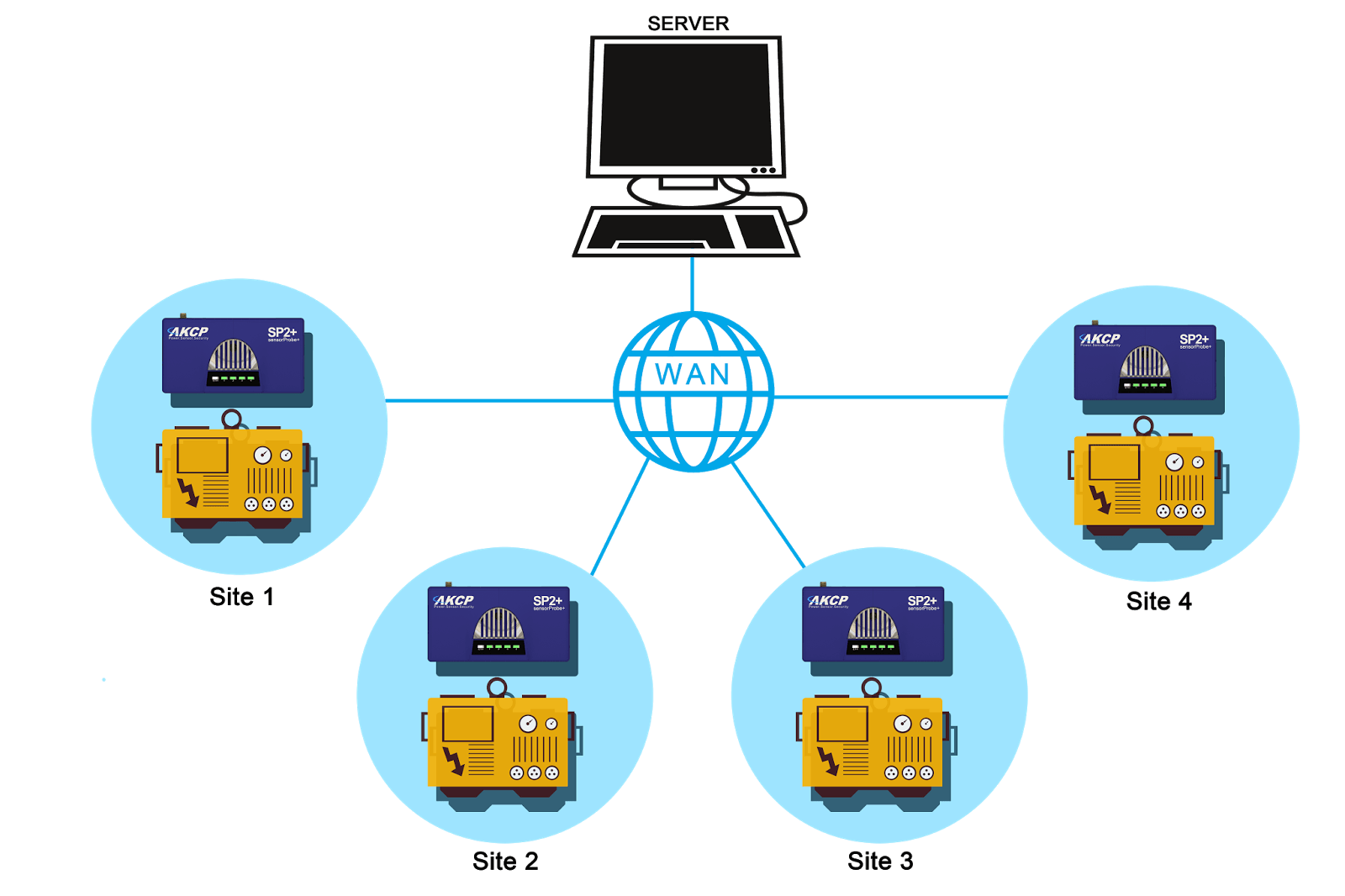

AKCP offers the ideal solution for generator monitoring, from 1 to 1,000 generators we have the system for you. By deploying the SP2+E device you can connect to the generator RS485 port and monitor all engine parameters you need. A 3G cellular data modem can be included as an option to allow alerts to be sent directly from the device. A built-in web interface gives access to data via the internet. AKCPro Server, a world-class central management software, gives you an overview of multiple sites. Customizable desktops and drill down mapping allow you to present the data from multiple generators in the format that suits you best.

The SP2+E has additional 3 sensor ports for connecting any of AKCP’s environmental, power or security monitoring sensors. For a complete monitoring system, you can add on an ultrasonic fuel level sensor for monitoring standby fuel tanks. Ensure that your fuel tanks are always full and ready to go, detect fuel theft and leakages and much more.