Photo Credit: www.raritan.com

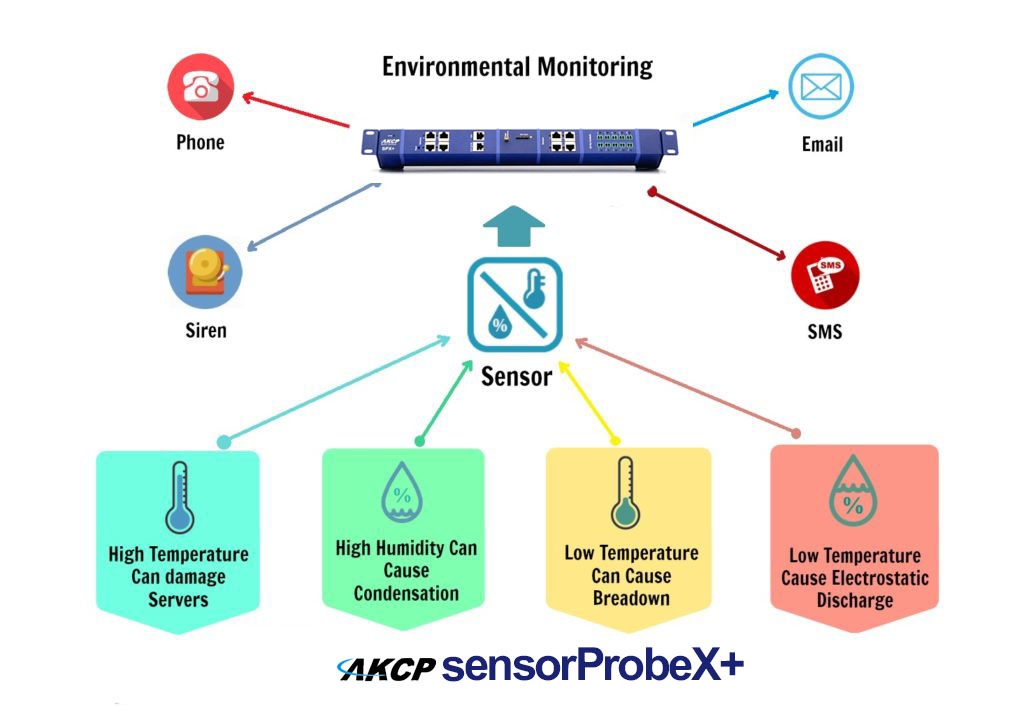

A data center should not mirror the conditions in a desert or a deli kitchen at dinner rush. To keep the data center equipment operating at optimal levels at all times data centers’ environmental monitoring system should always be ready to watch for temperature and humidity spikes.

What Parameters Should Be Part of a Data Center Environmental Monitoring Scheme?

There is no fixed template for an effective data center environmental monitoring scheme. Although there are definite guidelines from ASHRAE and Uptime Institute regarding the optimal conditions. Many factors come into play from the size of data center you are running, wether hyper scale or edge, to the security requirements and the ambient environment. But there are a few common factors to take into consideration in all data center environmental monitoring schemes. And here are some of them:

Temperature

Neither servers nor server racks should be allowed to exceed maximum inlet temperature levels. Most IT monitoring experts observe rack airflow exhaust metrics, internal system temperature levels, and even CPU temperatures. The faster the data provided by the temperature control systems reach the experts, the better they can enact pre-emptive measures before they turn into real headaches.

Humidity and Water Control

Chiller line water leaks and those from other sources are a surefire way to mess up your electronic systems. Too much humidity can also cause condensation, which can turn into water and wreak similar havoc on your servers and systems. Install water and humidity sensors to monitor these factors inside and outside of the rack.

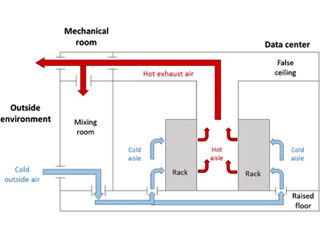

Aisle Conditions

Containment has become essential in the method of cooling management in data center environmental monitoring. This is why IT monitoring experts should deploy environmental sensors inside the hot or cold aisles. This provides a more precise image of what is happening inside a cooling zone.

Fire Suppression Monitoring

A lot of the big data centers have an operating fire suppression system in place, but they remain unused for a long time. In proper data center environmental monitoring practices, regular testing, and drills will ensure that these systems are not only operational but that the programs that govern them are all up to date.

Static Electricity Sensors

Electrical equipment that is not grounded properly or dry air can lead to dangerous static charges. The positioning of static electricity monitoring sensors at key locations in your data center can alert you to possible build-ups that can wreck your equipment.

Server Room and Rack Entry

Contact sensors in rooms and server racks can alert you to the presence of an open door that is letting the precious cooling out. It can also tell you if a room or a rack has been entered by intruders or unauthorized personnel. This is a good preventive against industrial sabotage. There are even cameras that automatically point to the specific rack or door that has been tampered with.

Are there Industry Standards for Overall Environmental Monitoring?

It’s difficult to pinpoint exact environmental monitoring methods that are optimal for all companies because they all depend on the size of the rack and the server room and what kind of equipment is housed within. Each setup requires a different set of monitoring equipment for basic environmental factors that should be closely monitored, and they are common to all data center configurations. The factors to be gauged will depend on the size and how complicated each setup is.

Temperature

Measuring temperature is always one of the basics when it comes to data center environmental monitoring. The recommended range for equipment security is between 70-74℉. ASHRAE widened these parameters in 2008 to 59-89.6℉. And in 2011, they extended it even more to accommodate more modern gear. It is now between 41-113℉.

Humidity

Humidity sensors are a must in all data centers that require environmental monitoring. Relative Humidity or RH is the ratio of moisture in a specific sample of air, matched to the maximum amount of moisture the sample could contain at that temperature. The prescribed RH is between 45% and 60%. Increased humidity can bring about condensation, which can lead to water build-up. Similarly, too little humidity can lead to electrostatic discharge or ESD. Both of which can do serious damage to your gear.

Water

Standing water should never be allowed in a data center. This is so that sensors can accurately read leaks and condensation issues.

Airflow

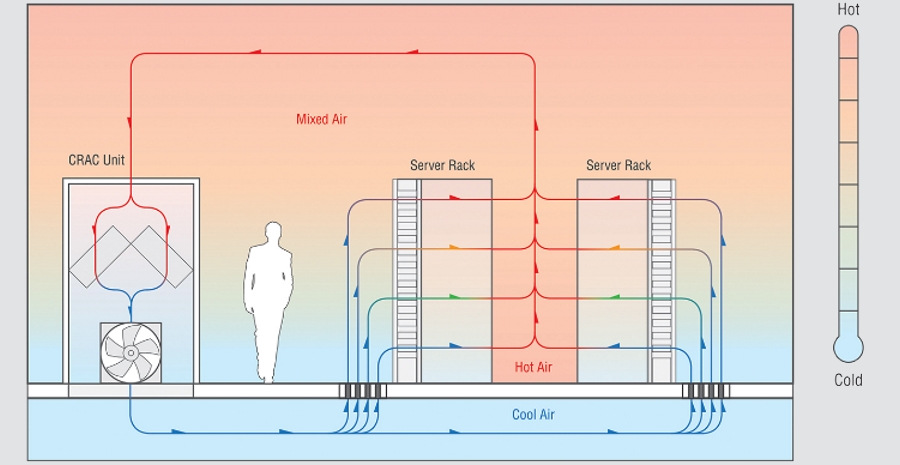

Proper regulation of airflow is essential in controlling temperature and humidity. The correct amount differs according to the size of the data center or server room or rack. Its readings are expressed as volume as cubic feet per minute (CFM). The precise volume of air needed directly correlates to the moisture content in the air and the temperature gradient between the supply air and return air. Try to prevent unstable airflow as this will manifest as a draft. In a tightly packed server room, the frequency of air changes in an hour will be much higher than that within a smaller space.

Computer Room Airconditioner/Handler

Vigilant and close monitoring is required for CRAC units. This takes into account supply and returns temperatures, internal humidity statistics, and air-loss percentages. Any perceived malfunction must be addressed quickly.

PDU and Electrical Systems Status

Electrical circuits within the designated workspace should be closely monitored for changes and interruptions. Any occurrence of these could lead to a mishap that could cause a shutdown of operations in your data center. Also, the data gathered from power distribution sites are utilized to calculate power usage effectiveness or PUE.

Do you know your PUE? Try our free online PUE calculator here.

Photo credit: www.dxlatest.com

How Durable and Reliable are today’s Environmental Sensors? How Often Should Sensors be replaced?

Environmental sensors keep you updated on the overall well-being of your data center. But even the best ones do not operate indefinitely. This is the reason why one should have multiple sensors within your workplace. Intelligent data center monitoring gear is capable of monitoring all sensors simultaneously and telling you when one, or more of them, has just malfunctioned. Sensor redundancy can prevent false-positives when a sensor breaks down. Environmental monitoring requires constant vigilance when the sensor malfunctions, a swift warning must be issued to the technician on duty to remedy the situation quickly. The same goes for incidences of data error and false alarms.

How Environmental Sensors be Placed? Any Tools to Help Sensor Placement around Servers, or Still a Manual Hit-and-Miss Process?

Each environment carries its own set of factors and parameters. No two are alike, there is no perfect place to put a set of environmental sensors. There’s a lot of trial-and-error going on when it comes to the correct placement of these devices. But HVAC and data center experts can do a lot of good if you consult with them. They can give you the best recommendations as to where to place your environmental sensors. So here are a few rules of thumb for your guidance:

- Temperatures are more likely to escalate near the top and the back of the racks. So this could be a good place to gauge airflow and exhaust temperatures.

- Temperatures tend to be cooler at the bottom and front of the racks. So this is where you read your intake temperatures.

- Humidity is more concentrated in warmer air, which carries more moisture. So disperse humidity sensors in elevated areas free from obstruction and far from heating or cooling sources.

- Position water sensors in low places like the bottom of racks or adjacent to drainage grates. Make sure it is lower than any elevated floor.

photo credit: /www.netpingdevice.com

How do Environmental Monitoring Tools Interoperate with Administrator-Focused Systems? How these give Companies a Complete Picture of happenings in the data center?

Big data centers must have the ability to look at the entirety of their workplaces and see everything. This is not limited to environmental input but extends to server metrics also. The equipment is used to gauge power consumption, CPU, RAM, and other essential technologies working hand in hand with environmental monitoring systems. For instance, AKCP Monitoring Solutions. carries a line of appliance-based monitoring equipment and sensors for complete monitoring.

But in the end, the operational efficiency of a data center depends on the effectiveness of communication among the data center teams. The gear used is simply a tool that guides. The corresponding engineers and managers must receive the correct data from the server, data center, and virtualization teams. They must work hand in hand to create the perfect environment for all equipment within an operational data center.

Conclusion

We have answered in this article five commonly asked questions about data center environmental monitoring. We have provided you input and advice as to the best place to position your monitoring gear, as well as what factors to watch out for when trying to maintain an optional environment for your workplace. We hope this article was both informative and helpful.

References:

https://www.sensaphone.com/industries/data-center

https://www.raritan.com/blog/detail/data-center-environmental-monitoring-best-practices