Data centers come in many sizes, from small server rooms, to edge data centers and massive hyper-scale facilities. The industry has grown from being a small-scale to a hyper-scale business. The growth is due to the world’s ever-increasing reliance on technology. The need to improve efficiency has become crucial as data centers consume an increasing amount of resources.

Many businesses now rely on data centers as they shift to virtual offices and cloud platforms. These facilities consume enormous amounts of energy and water. Efficiency is a priority to reduce costs and maintain environmentally friendly operations.

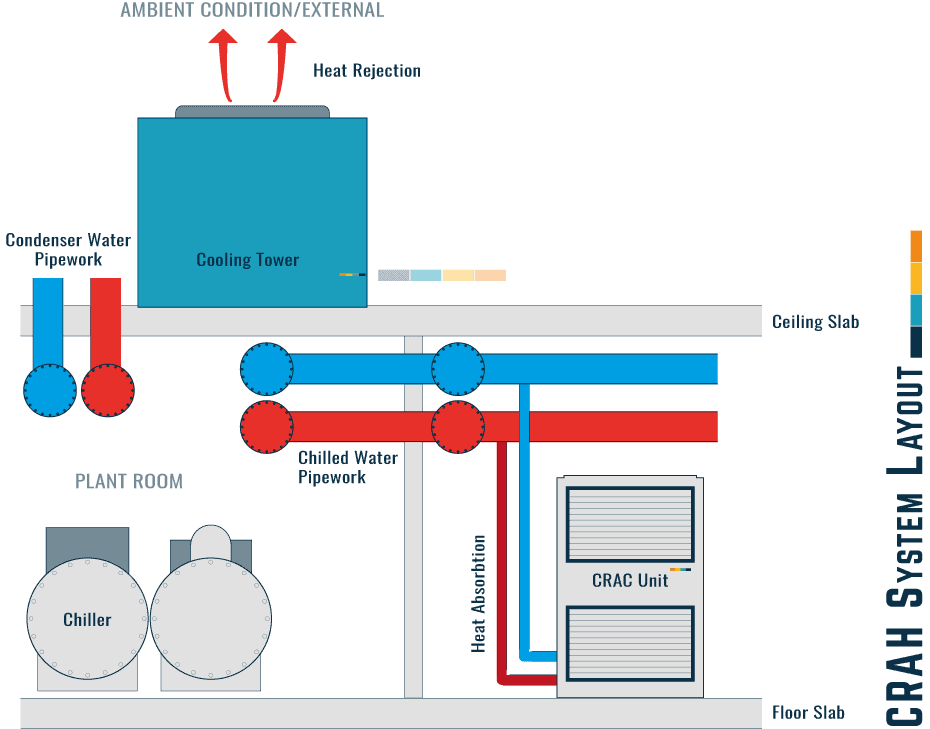

Cooling systems are essential in data centers. They remove heat that is a byproduct of the servers and keep the right temperatures for the IT equipment. Specially designed cooling systems are deployed in large data centers. These are known as Computer Room Air Handlers (CRAH) and Computer Room Air Conditioners (CRAC).

Air conditioning (AC) units blow air over cooling coils with refrigerants to keep electrical systems cool. Computer room air conditioning (CRAC) units work like AC units. But they do not only provide cool air. They also maintain temperature, humidity, and air distribution, which are vital in server rooms.

The latest cooling method is computer room air handler (CRAH) units. These utilize chilled water to cool server rooms and electrical systems. This article focuses on CRAH units as they provide energy efficiency and cost benefits.

Data Center Cooling Design

Operating servers 24/7 generates significant amounts of heat inside the data center facility. Servers are prone to overheating and shut down with thermal overload. They also will have shorter lifespans if operated at elevated temperatures. Overheating also disrupts business operations, leading to lost revenue. Cooling systems are therefore vital to remove heat. The cooling design is essential to keep data centers running at their best. However, cooling systems consume large amounts of energy and water.

Containment strategies are used in the design of data centers. This improves efficiency by preventing hot and cold air from mixing. By analyzing the way air is moving in the data center you can ensure that the cold air is taking the optimal path to the IT equipment. We have two types of air cooling designs that will be discussed. Both use heat exchangers but differ in the airway and cooling strategy.

-

Direct Aisle Cooling (DAC) System

A coil pack is placed at the top of the contained aisle, which makes a ceiling. Heated air from the equipment is brought to heat exchangers. Exhaust air is then cooled down before going back to the aisle. This system is much more versatile than RAC as it only needs enough ceiling height. It is also typically used for larger installations.

Hot air goes through the air-handling area via corridors or ducts. The hot air is cooled down through heat exchangers, which are returned to the aisle via corridors. These corridors lead cooled air to vents, leading to raised floors and back to the aisle. Compared to the DAC system, this one can be more optimal as it accommodates several aisles. It also allows for functional tailoring for mass cooling.

Integrating CRAH Units In Cooling Systems

Photo Credit: constructandcommission.com

CRAH units work like CRAC units. They use fans to blow over cooling coils and reject hot air. But CRAH cooling coils use chilled water instead of refrigerants. A separate chilled water plant or chiller supplies chilled water to the CRAH units. Hot air is collected from the server room, and this air goes through cooling coils. Heat is then transferred from air to water, returning to the chiller.

CRAH units can control fan speed to maintain temperature and humidity levels inside the server room. These units are used in medium to hyper-scale data centers. These units are more energy efficient as they use less energy and do not need much maintenance.

In the cold aisle system, CRAH units collect the heat coming from the equipment. This hot air is cooled and ejected into the space under the floor. It is then circulated back to the server rack from below. A hot aisle system works similarly to cold air applications. It takes the hot air from the floor below, then cools down the air. The cooled air is expelled above and circulates throughout the server room.

CRAH units are mounted above server racks in DAC systems to create an enclosed aisle roof. This system does not need raised floors. CRAH units are easy to mount and can be standardized. High-performance coils and energy-efficient fans offer money-saving benefits for operators.

Furthermore, mounting CRAH units above the server racks makes maintenance easier. It optimizes floor space for the servers and improves hot/cold aisle containment.

Considerations For CRAH Units Design In Data Center Cooling

Photo credits: nypost.com

While CRAH units can be beneficial to your facility, make sure to consider these things first.

- Airflow. It is a vital consideration in CRAH design to ensure efficiency and efficacy. Installing CRAH units to your cooling system requires certain configurations. The right layout will bring the most optimal configuration for your data center.

- Frontal/up flow. It is typically used in IT rooms, electrical switch/rooms, and UPS. Hot air goes into the CRAH unit’s lower frontal section. The air goes upward to the cooling coil to be cooled down. The cooled air is blasted back to the upper frontal part.

- Downflow. They are typically used in facilities with CRAH units with a fan wall. Hot air is pulled down from the server room to be cooled. It is then directed through the top of the CRAH unit and dragged downwards via the cooling coil. Hot air is cooled down before being blown back into the space through the unit’s bottom frontal section.

- Demand and profile. To reach optimal PUE, ensure cooling equipment can achieve the right temperature profile at a small air volume. It will reduce the mechanical strain on the cooling system. It will also need fewer materials and energy consumption.

- Drop chassis CRAH. Ceiling height can also affect the efficiency of CRAH units. Lower CRAH fans tend to increase in air-side pressure drop due to restricted air-space aisle. It poses a particular risk in DAC systems as restricted air discharge might lead to suboptimal performance. Operators may opt for draw-through or blow-through configurations.

- Draw through. Air goes through the cooling coil and is discharged to the cold aisle.

- Blow through. A fan is mounted in the air entry area. Air goes through the cooling coil and continues circulation in the cold aisle

- Fluid flow balance. Flow rate is regulated to balance capacity and fluid temperatures via the CRAH unit. Higher flow rates lead to less fluid outlet temperature and reduced capacity. Find the operating point that can fulfill air volume, temperature, and capacity requirements to reach a balance. A crucial part of the CRAH design is the entering water temperature (EWT). Typically, lower EWT has higher demands for heat rejection (HR) units. It restricts free-cooling greatest operating temperature, hence, limiting free-cooling potential. EWT must be balanced with free-cooling potential and aisle temperature requirements. Lower aisle temperatures lead to less free-cooling potential. In contrast, higher aisle temperatures cut computational efficiency.

- N+x redundancy mode. N redundancy is the basic required component of an IT system. It serves as the basic level wherein IT systems must build on top. There are many types of N+x configurations. In the active configuration, a redundant component operates with an original component. If the original component fails, the redundant component will run. In the passive configuration, the redundant component must first be activated before operating. The redundant component fulfills the availability gap in standby or load sharing configuration until the original component entirely works.

- Temperature profiles. Heat rejection (HR) is a crucial aspect of cooling designs. Dry air coolers affect ambient temperatures that determine PUE. Due to diminishing exchange, chillers can only cool liquid from higher temperatures than ambient. Up to 3 degrees higher than ambient. Moreover, inlet water for CRAH units must be 3 degrees Celsius lower than cold aisle temperature.

- Physical conditions. Structural considerations are also vital in CRAH design.

- Aisle dimensions. Examine ceiling heights, aisle length, and width. CRAH units in DAC systems maximize coil surface area in room space. In RAC systems, CRAH units are installed in a remote location. Hence, the equipment is free from aisle containment.

- Materials and construction. Examine the coils, fans, and copper tubes of the equipment. Operators can also retrofit controls for the data center facility.

- Surface density. HR limits space availability for CRAH units. Hence, optimizing surface density is essential. When there is little room for CRAH design, it can compromise the entire cooling design. Smaller tube configurations and tighter spacing will help solve this issue.

- Thermal conditions. Cold aisle containment tends to be affected by the height of contained volume. It needs adequate space to reduce the impact on fan performance. Typically, containment strategies do not affect CRAH design. But it is still important to consider the varying configurations of hot/cold aisle containment.

Optimize Your CRAH Units With AKCP Data Center Monitors

Efficiency is a key aspect of data centers. Track your cooling system to ensure optimal performance and effective cooling design. AKCP offers the best monitoring solutions for all your data center needs. We provide environmental, power, and airflow sensors to help optimize your facility.

AKCP Air Velocity Sensor and Airflow Sensor

They are designed for systems that generate heat. The steady flow of air is necessary to dissipate heat to maintain system reliability and safety.

AKCP Air Velocity Sensor

- Air Velocity Sensor

The Air Velocity Transmitter sensor is placed in the path of the air stream, where the user can check the status and the amount of airflow. The sensorProbe or securityProbe web interface shows this information using a percentage and graphical display. It also graphs the analog values over some time. If, for example, the airflow decreases, the web interface will show any sign of change over time.

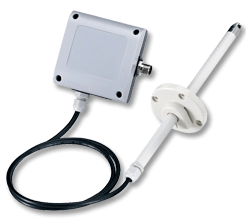

- Airflow Sensor

AKCP Airflow Sensors

The Airflow sensor is placed in the path of the air stream, where the user can track the status of the flowing air. The airflow sensor is not a precision measuring instrument. This device is meant to measure the presence or the absence of airflow. Besides the sensors’ ON or OFF status, the airflow sensors’ condition can also be read via an SNMP using its OID. SNMP traps are sent when critical. SNMP polling via getting available. Web browser interface available. When an alarm condition is activated, it can send the description and location of the fault via an email page.

It is not a precision sensor. It is only designed to sense the presence and non-presence of airflow and not to measure the amount of airflow. It is best used to send an alert when a fan, AC failure, or airflow is present when it should not be.

Conclusion

CRAH unit is a device used to remove heat from the equipment. It uses cooling coils and fans to reject heat. Thus, creating an effective way of cooling the equipment. Integrating CRAH units into your cooling systems can improve efficiency and savings for your facility. But certain considerations should be taken into account before doing so.

Airflow is one of the biggest considerations in cooling systems. It affects the efficiency and performance of data centers. CRAH units play a key role in making an effective airway for cooling. Make sure to configure your design effectively. Above all, incorporate an air velocity and airflow sensor to fully optimize your data center cooling system.

Reference Links:

Focus_DCC_FocalPaper_CRAH.pdf

https://www.atisolutions.com/faqs/the-importance-of-crahs-and-cooling-in-data-centers.cfm

https://dataspan.com/blog/crac-vs-crah-cooling-units-whats-the-difference/

https://www.sunbirddcim.com/glossary/computer-room-air-handler-crah

https://www.bmc.com/blogs/n-n1-n2-2n-3n-redundancy/