Data centers contain different types of equipment that keep the IT operations running. These equipment are sensitive and prone to damage when not protected. Data Center Facility Administrators monitor the environment inside at all times, tracking different environmental variables that affect the data center’s performance. The monitoring helps them know any potential incident that requires corrective action. One of these is monitoring indoor air quality through an air quality sensor.

Indoor Air Quality (IAQ) refers to the quality of air within and around the data center. Its impact is not only limited to people working there but also the well-being of the equipment is also at stake. This variable can result in big devastation when left unchecked.

What is Ideal for Data Center?

Having the right temperature and humidity control is necessary for data centers. Equipment is made up of metal and non-metallic materials. These elements are vulnerable to corrosion. Corrosion slowly destroys the equipment leading to complete failure. Some data centers have reported server and hardware failures due to this. To ensure the best quality of air inside data centers, the air demands to be filtered out from external pollutants and toxic chemicals before going inside the data centers. This way, the deterioration of air quality due to pollution can be prevented.

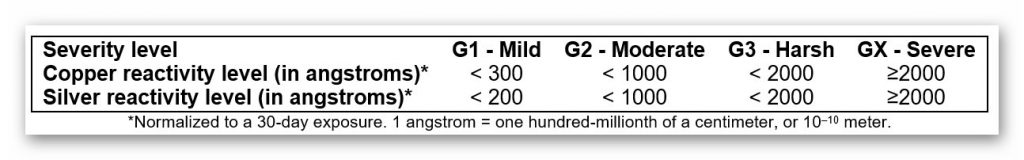

The Restriction of Hazardous Substances (RoHS) directive made the IAQ a major issue. It was first passed in the European Union 10 years ago. After that, several countries also passed their version of the law. In this directive, the use of hazardous substances in data center equipment is restricted. Due to this, many companies have updated their air quality specifications. This update includes compliance with the International Society of Automation (ISA) Standard 71.04. The standard aims to calculate the corrosive potential with regard to electronic equipment. This is through comprehensive corrosion monitoring. To help administrators identify what level of severity they are facing, the standard also gave a classification in environmental severity levels for electronic systems.

Severity Level G1

Mild. An environment is controlled enough. Corrosion is not an issue in determining the equipment reliability

Severity Level G2

Moderate. An environment in which the impact of corrosion can be measured. Corrosion can be an element in determining the reliability of equipment.

Severity Level G3

Harsh. An environment in which high possibility that a corrosive attack will happen.

Severity Level GX

Severe. An environment in which only specially designed and package equipment is expected to survive.

Photo Credit: www.purafil.com

Impact of IAQ on Data Centers

Outdoor pollution has been a great problem ever since. Its effect on the people and businesses is undeniable. The myth that indoor air is not dangerous needs to vanish now. The impact of IAQ on data centers has to be recognized. Companies should take action about it before incurring a big loss.

Both inside and outside factors contribute to airborne contamination. Outdoor contaminants include dust, pollen, and air pollution. These pollutants enter the facility through people entering and exiting. They can also be brought inside via skin, clothing, and hair. indoor contaminants are particles from the facility and regular operation of machines. Particles from dirty HVAC units and floor tiles are some of these. Aside from equipment failure, the thickening layers of dust and particles in HVAC systems increase energy usage, hence, the operation cost of the data center.

Sulfur dioxide and Nitrogen dioxide are strong chemicals. High levels of these gaseous contaminants in the air may lead to corrosion of electronic equipment. These gaseous contaminants are usually the products of fossil fuel combustion.

How Corrosion Affects Electronic Equipment?

Salt in the air inside the data center increases because of air pollutants. Salts and other acidic gases are the main generators of electronic equipment corrosion. However, it can also be a result of caustic and oxidizing gases. These include Hydrogen Sulfide, Sulfur and Nitrogen Oxide, Chlorine, and Ozone.

Equipment failure, inefficiency, and increase in maintenance costs are all impacts of corrosion. Specifically, it can affect the following components:

Film Disk- Risk of losing the stored information at the reaction site.

Edge Connectors- These connectors are usually located at the end of the circuit board. They contain copper or gold and nickel. Corrosion can easily destroy the connector points, affecting data transfers.

Disk Drives- these are made of materials that are vulnerable to electronic corrosion even in indoor conditions.

Photo credit: www.hzo.com

Countering Contaminants

The data center needs to provide crucial service. They have to comply with strict standards. To function well, clean and cool air is vital. However, airborne contaminants hinder data centers in achieving it. They damage the equipment causing downtime and increasing cooling costs.

To counter this, having an Air Filtration System and Air Quality Monitoring is important. It keeps the data center safe from the threat of sudden failure due to Air quality. Air Filter negates all the impact of poor indoor air quality. It keeps the air clean inside the data center. It also blocks external pollutants from entering. In addition, air filters lower energy expenses. They can cut the bills from 30-40 percent or more. These filters come in different size ranges and capabilities to comply with the data centers’ needs.

If a data center is located in polluted surroundings the more prone it is to contamination. These polluted areas can be anywhere near sewers or drains, landfill sites, and those with high-density traffic. Companies can counter this by having additional chemical filters. These filters are placed at the fresh air inlet of the HVAC unit. This eliminates all the gaseous contaminants that are harmful to the data center.

How to Monitor Indoor Air Quality in Data Center?

With all the effects of Indoor Air Quality on data centers, consistent monitoring is required. This is a critical process to optimize data center efficiency. Hence, it should be part of the overall data center management strategy. Air Quality sensors for identifying the levels of contaminants should be set up inside the facility. This allows facilitators to take action before big problems occur.

Good thing an industry leader knows all the risks. AKCP has developed various products to help data center operators. They offer systems that provide accurate and actionable data about the IAQ condition of data centers.

Wireless Tunnel™ Air Quality Sensor

AKCP provides Wireless Air Quality Sensor that will bring significant change to how your data center works. It is a combination of Air Particles, Metal Oxide gases (MOx), Temperature, and Humidity in a single sensor.

An air particle sensor can be utilized during indoor air quality (IAQ) assessments. The specific type of particles is not detected, but it can measure the mass concentration of particles in the PM1.0 to PM10 range and particle number concentration in the PM0.5 to PM10 range. Which identifies the quantity or mass of airborne particles that could be sourced from:

– Exhaust smoke

– Airborne dust particles

– Pollen

These airborne pollutants can be a health hazard, and result in sneezing, headaches, asthma, and so on. In addition, during many agricultural and industrial processes, airborne dust can be a serious hazard forming combustible dust clouds.

References Links:

https://greenfieldsoft.com/why-is-monitoring-air-quality-within-data-centers-so-important/

https://www.achrnews.com/articles/135527-ensuring-proper-air-quality-moisture-levels-in-data-centers

https://www.advfiltration.com/blog/what-you-need-know-about-air-quality-data-centers