Data centers are an essential part of modern business. They store, process, and analyze large amounts of data. To optimize the equipment, increase reliability and longevity it is important to keep their environment regulated. With the help of temperature sensors like Temperature and Humidity, Airflow, Air Quality sensors, monitoring your data center for optimal PUE is possible.

Data Center’s operation is non-stop. They consume large amounts of power, and a byproduct of the power is heating. Without the right HVAC system, the temperature inside the data center increases. The HVAC system cools the air and keeps the environment of the data center suitable for server operations.

It is important to monitor the cabinets that house the servers. The American Society of Heating and Air-conditioning Engineers (ASHRAE) standard temperature is between 59°F or 89.6°F, as well as 20%RH to 80%RH. Still, some data centers maintain an even lower temperature, to make sure the performance of the server units when running at total capacity.

High temperatures can lead to unnecessary downtime. Temperature sensors are installed at specific points in the data center to monitor the condition of the facility in real-time. This data delivers alarms for incidents caused by changes in temperature and humidity. Then, the technical team can make data-based decisions or preventative actions. Sensors also help the technical operators to determine the exact location of the problem.

Where Should You Place Temperature Sensors?

The proper placement of sensors within the data center is another critical part of the overall monitoring strategy. They should be placed in areas where they can provide the most accurate data.

A temperature sensor placed in the rack system can measure the temperature within that rack. However, it won’t be able to monitor the room temperature accurately. Therefore, it is the first thing to do to decide what specific area you would like to monitor. Is it the temperature within the racks? Or the ambient room condition.

In-Rack and In-Room are two major go-to for temperature sensor placement. Both approaches provide significant information to the data center condition. Understanding each will result in improved decision-making.

In-Rack Temperature Sensors Placement

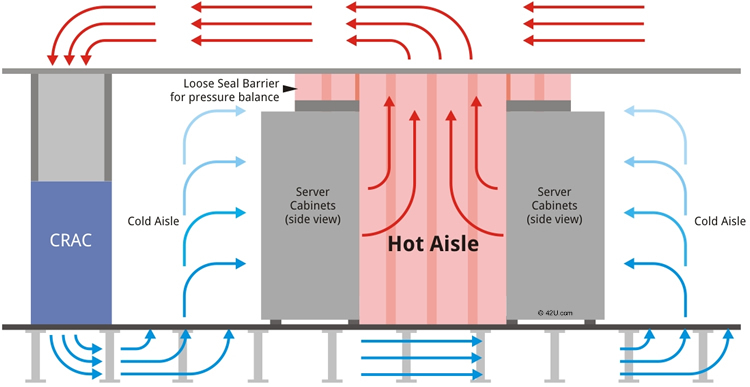

The air temperature can be different in every rack. It also depends on the cooling system. To generate the most accurate reading, it is best to place them nearest to the units.

An experiment conducted in a non–temperature-controlled environment showed the temperature within a rack can vary by 194 °F (80°C). In this case, to read the highest temperature, place sensors at the top of the rack. As warm air rises the top of the rack is the hottest part of the rack.

However, it is also important to scrutinize other areas of the rack. This is especially for data centers with multiple servers and computers. You can mount them at the top, bottom, center, and other areas as needed. The ASHRAE suggests having a minimum of 6 sensors per rack level to ensure the equipment’s safety. Sensors such as the AKCP Temperature sensors are ideal for meeting this standard.

Recommended specific temperature sensors placement also includes:

-

Next to the thermostat controlling the room temperature

-

The front door of each rack

-

Midway on the back of each rack

-

On each air circulation plenum space

Knowing the movement of air throughout your rack is essential in temperature sensor placement. It is also most effective to avoid direct airflow in placing temperature sensors. Direct airflow on the sensor chip can skew data, thus providing an inaccurate reading. Fluctuation in temperature and humidity often happens in these positions, creating a false alarm.

Placing multiple sensors around the rack ensures the highest point of protection. Sensors should have different alarm thresholds focusing on each location. This will provide you with a more definite map of in-rack temperature conditions and reliable alarms.

In-Room Temperature Sensors Placement

In-room temperature sensors are designed to monitor a broader area, such as the room temperature. They do not provide the temperature of specific points on the rack, but they measure the whole room temperature in general.

Placing these sensors has nearly the same scope of conditions as In-Rack sensors. As with the in-rack, it is not advisable to place sensors over the direct airflow. In addition to this, avoiding the sunlight depending on location is also critical for in-room temperature sensors. For example, if a sensor is placed near the doors, it can inaccurately read the temperature as overheating. This is the same with placing sensors near equipment emitting hot air.

In-room temperature sensors are usually deployed on potential hot zones areas. On the contrary, others place near air-conditioning units to detect if those systems failed. However, data centers still vary in location, layout, and size. In this case, a trial and error approach of placing sensors on different areas within the data center is recommended. It helps you identify the areas where the temperature sensors work most effectively.

Another consideration is the size of the room. For smaller rooms, using wired sensors is recommended. For large rooms with different monitoring points, a wireless sensor is a practical choice. This is easier to install as there is no drilling required in installing.

Photo Credit: www.upsite.com

How Climate And Weather Conditions Affect Data Centers?

Data centers are situated in different places. External factors such as climate and weather influence the data centers. Understanding the geographical characteristics of the data center’s location allows you to respond to different circumstances.

For example, If the data center is located in higher temperature areas, cooling systems are adjusted. Likewise, for data centers located in areas with a long winter season. They run supplemental heating to keep the outdoor component of the HVAC system from freezing up. Aside from heat and snow, natural disasters such as storms, rain, and humidity are to be considered by data center administrators.

No one knows when the temperature fluctuations due to weather and natural disasters are going to happen. A study says some small businesses never got back on the operation after a disaster. This is mainly because of the loss of data. Nonetheless, being proactive is the key to maintaining the internal environment of data centers. Using temperature sensors, data of fluctuations caused by the external environment will be provided before a problem occurs.

Photo credit: fortune.com

Knowing Your Humidity Threshold

Understanding the temperature alone is not enough for effective sensor placement. As air temperature increases, the humidity decreases. The humidity threshold is critical to data centers as the equipment is sensitive to moisture.

The standard Relative Humidity (RH) recommended by ASHRAE for data centers is between 20% and 80% RH. The goal is to stay close to 50% as much as possible. Too much dryness can intricate Electrostatic Discharge (ESD). The build-up of static electricity causes ESD on the system. It is one of the major problems electronic equipment manufacturers are facing. On the other hand, being too humid can lead to corrosion. Corrosion slowly destroys the equipment resulting in complete failure. One of the most common examples of corrosion is rusting.

Like in temperature, knowing the humidity threshold and setting an alert for fluctuation is important. This allows you to know your data center’s humidity condition and have more time to take action if necessary.

Proper Airflow Management

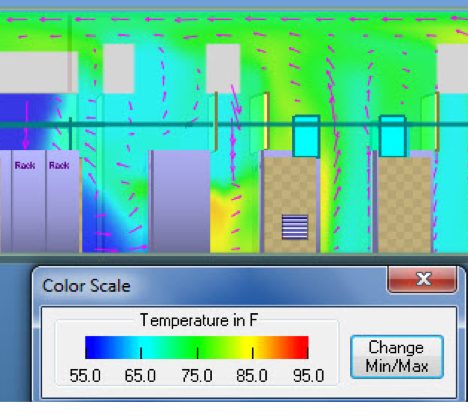

Inefficiency also happens when airflow is neglected. The high-density equipment inside data centers makes ASHRAE cooling failure possible. The study from Up Time Institute shows that 10% of racks run hotter than recommended. This can lead to a more hot spot on the racks. A hot spot is any hot area or point in the data center in which temperature is beyond as recommended. This happens not because of insufficient air cooling. There may be enough cooling capacity, but it cannot go to where it is needed because of poor airflow management.

The hot spot can be addressed using a temperature sensor. As sensors indicate how hot the specific area is, a hot spot can be easier to identify. Therefore, this allows you to improve your data center airflow plan before temperature surpasses its threshold, causing damage to the data center.

Photo Credit: .bitcointalk.org/

Data Center Temperature Monitoring

The bigger market for data centers calls for improved performance. With growing users, it is essential to catch up with the business-changing demands. Efficiency and safety have been always the challenge. It is a good thing that a reliable and leading sensor monitoring company like AKCP has a variety of Wired and Wireless Temperature and Humidity monitoring sensors for your data centers.

AKCP Data Center Temperature Sensors is the best way to avoid hotspots in IT cabinets or server racks. Ensuring equipment is running at optimal temperatures will increase its lifespan, reliability and decrease maintenance. ASHRAE recommended standards for data center cooling are a guideline for the temperatures at which a data center should run.

AKCP temperature sensors and cabinet thermal maps monitor your data center and IT cabinets. Use collected temperature sensor data to safely raise air conditioner temperature setpoints without putting mission-critical equipment at risk.

Save on server room cooling costs and lower server room PUE one rack at a time.

For Inquiries, you may reach us through our sales team: [email protected]

Reference Links:

https://www.ametherm.com/blog/thermistors/temperature-sensor-types

https://www.pyrosales.com.au/blog/news/how-do-temperature-sensors-work/

https://www.elprocus.com/temperature-sensors-types-working-operation/