In the digital world, everyone depends on machines, applications, and online information. People access this using multiple channels at any given time. To deliver these services, enterprises rely on data centers in performing their daily operation. The data center components need to be run at a cool temperature to prevent interruption. With the use of a temperature monitoring system, administrators ensure uptime and continuous business operation.

But What Exactly Is A Temperature Monitoring System?

The data center facility is monitored with temperature sensors providing real-time information on the facility environment. A data logger collects data from the sensors and stores the values, creating a graph. Alerts are generated when temperatures surpass the safe level.

The usual concern of the data center is temperature rise. It causes overheating and increases energy consumption. However, temperature drop also requires action. In addition to overcooling being a waste of energy, when temperatures drop, relative humidity increases which has consequences such as mold growth and corrosion.

Having the right temperature monitoring system allows administrators to keep track of temperature changes. Anticipating problems using the intelligence of the system is a more practical option rather than repair. Also, maintenance of the data center at the correct range ensures efficient use of cooling energy and servers.

Benefits of Temperature Monitoring System

Most data centers rely on a temperature monitoring system. It has become mainstream in the industry. According to research, the temperature monitoring system is projected to grow at a Compound Annual Growth Rate (CAGR) of 3.9% from 2018-1014.

This system has a lot to offer to the data centers if appropriately utilized. With this, administrators can be confident with the data center’s operation.

Preventing Downtime

The temperature is an important parameter for the equipment’s functioning. Computer systems are designed to work best when the ambient temperature ranges from 20-23° Celsius. This is achieved through an automated temperature monitoring system.

When cooling fails, hot air exhausted by the server becomes dominant. If the temperature is not maintained, downtime will happen. And downtime costs both time and money. Based on Gartner, data center downtime costs approximately $5,600 per minute or up to $540,000 per hour. With a temperature monitoring system, administrators will be notified promptly. This allows them to take alternative actions to lower temperature and prevent downtime.

Keeping Records

The temperature monitoring system will automatically generate reports. The data will be kept as a record that can be accessed in the future. Significant decisions are affected by the records leaving no room for human error such as incorrect or lost records. Unlike manual recording, the monitoring system delivers data with little to no error.

Automatic Alerts

It is easier to customize indicators for minimum and maximum thresholds based on ASHRAE with a temperature monitoring system. Temperature monitoring systems send alerts on changes in the temperature that is set. There is no need to manually check it from time to time to see if there’s a rise or drop in temperature. Additionally, after receiving the alert, administrators can quickly contact the personnel to act upon it.

Energy Efficiency

Photo Credit: www.colocationamerica.com

Consistent data records provide the pattern in the temperature. This helps know if the cooling capacity suffices the need for the equipment. Or if there’s possible action for cost savings. Generally, the cooling units are set to maximum to ensure low temperature. However, this practice is far from energy-saving as excess cooling is being wasted. Using temperature sensors, the administrator can have information about the supply and return temperature. They will be guided on decreasing or increasing the cooling. Moreover, they will be able to find the perfect temperature for reliable equipment and efficient energy consumption.

Sever Room Planning

The data provided by the temperature monitoring system can help administrators decide where to put additional equipment. It is a critical decision as it increases hot airflow in the facility. They can also have insight on what layout to use to prevent disrupted airflow or mixing of hot and cold air. A monitoring system can work with a CDF Analysis to get a comprehensive vision of data center scaling.

Factors in Selecting Temperature Monitoring System

The need for a temperature monitoring system in keeping the equipment has been recognized over the years. Yet, many still lack the knowledge of selecting the best one to achieve maximum safety. There are a variety of temperature monitoring systems available in the market, which makes choosing one more difficult. Options differ in price and features.

Good thing, some factors serve as guidance in choosing the right one for you.

Accuracy

- The accuracy of the temperature data relies on the quality of the temperature sensor. It should be placed on surfaces or near the areas that are being measured.

Promptness/Timeliness

- another factor is the ability of the temperature monitoring system to send notifications without delay anywhere in temperature, every second count. The earlier the issue is discovered, the less damage it would have.

Accessibility

- one of the core requirements of a temperature monitoring system is easy to access data. Administrators are not necessarily to be on the data center to keep track of the temperature. This feature is one of the greatest strengths of the wireless system.

Storage

- This depends on the recording application. Data storage varies with the amount of data that is needed to store for analysis. Some store only a minute’s worth of data while other stores have years’ worth.

Security

- To prevent inaccurate data and false alarms, it should be secured from hardware and software issues and malfunction.

Types of Temperature Sensors

Photo credit: realpars.com

The key to an effective temperature monitoring system is a reliable temperature sensor. The temperature sensor is a device connected to the system to gather data on the environment.

It could be an analog or digital sensor. For which is better, there is nothing other than the other. There are considerations like facility design, application, and deployment. Analog sensors are smaller and more convenient to install. These are more appropriate for beginners. However, they do require an analog-to-digital converter (ADC) to read the output. On the other hand, digital sensors have greater accuracy. They are larger making them quite difficult to install. Digital sensors may include additional features. No additional circuitry needs to be built if the chip is on a breakout board. These sensors are not as likely to be affected by the power supply and other components in the circuit.

Temperature Sensors Placement

Room and Rack Temperature Monitoring

Another critical aspect of a temperature monitoring system is the proper placement of sensors. They have to be placed properly to have an accurate reading. Generally, sensors are placed based on what is to be measured. Is it the rack temperature? Or the ambient temperature? There are two options for sensor placement.

It is usually placed on the top, middle, and back of the rack for rack temperature. Air temperature can be different from rack to rack. In-rack placement measures the inlet and outlet temperature. ASHRAE recommends placing a minimum of 6 sensors per rack.

Ambient temperature can be measured through In-room sensor placement. It helps administrators to track the overall temperature of the room as a whole. When placing in-room sensors, it is important to avoid direct sunlight and doors as it can cause a false alarm.

AKCP Temperature Monitoring Solutions

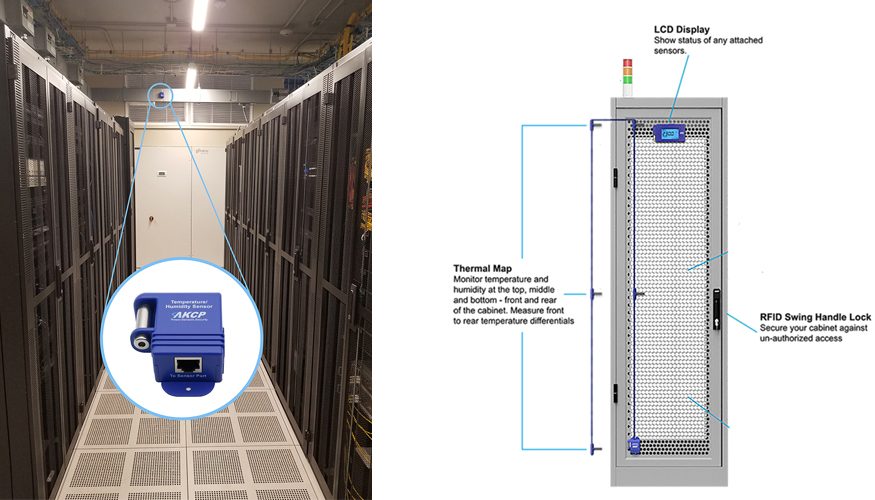

AKCP provides monitoring solutions for critical mission facilities like a data center. When looking

for a reliable sensor for your computer room or rolling out a multi cabinet monitoring solution, AKCP has an end-to-end data center monitoring solution including sensors. It also offers AKCPro Server DCIM software. Our Rack+ solution is an integrated intelligent rack or aisle containment system. Pressure differential sensors check proper air pressure gradients between hot and cold aisles. RFID Cabinet locks secure your IT infrastructure. Sensors have wireless capabilities for easier monitoring. It has a built-in calibration check sending a notification if it requires re-calibration.

Guarantee your uninterrupted business operation and improve your temperature monitoring system. Message AKCP now!

Reference Links:

https://www.dpstele.com/blog/temperature-monitoring-system-how-works-choose.php

https://www.techbriefs.com/component/content/article/tb/pub/features/articles/35462#:~:text=Temperature%20monitoring%20systems%20capture%20temperature,such%20as%20a%20thermocouple%20probe.&text=The%20three%20most%20common%20temperature,the%20most%20common%20temperature%20sensors

https://www.marketsandmarkets.com/Market-Reports/temperature-monitoring-system-market-250125379.html

https://www.enviromon.net/5-benefits-of-temperature-monitoring-for-server-rooms/

https://www.raritan.com/assets/ram/resources/white_papers/raritan-wp-Env_Monitoring_White_Paper_070913.pdf