Photo credit: www.jcmtech.co.za

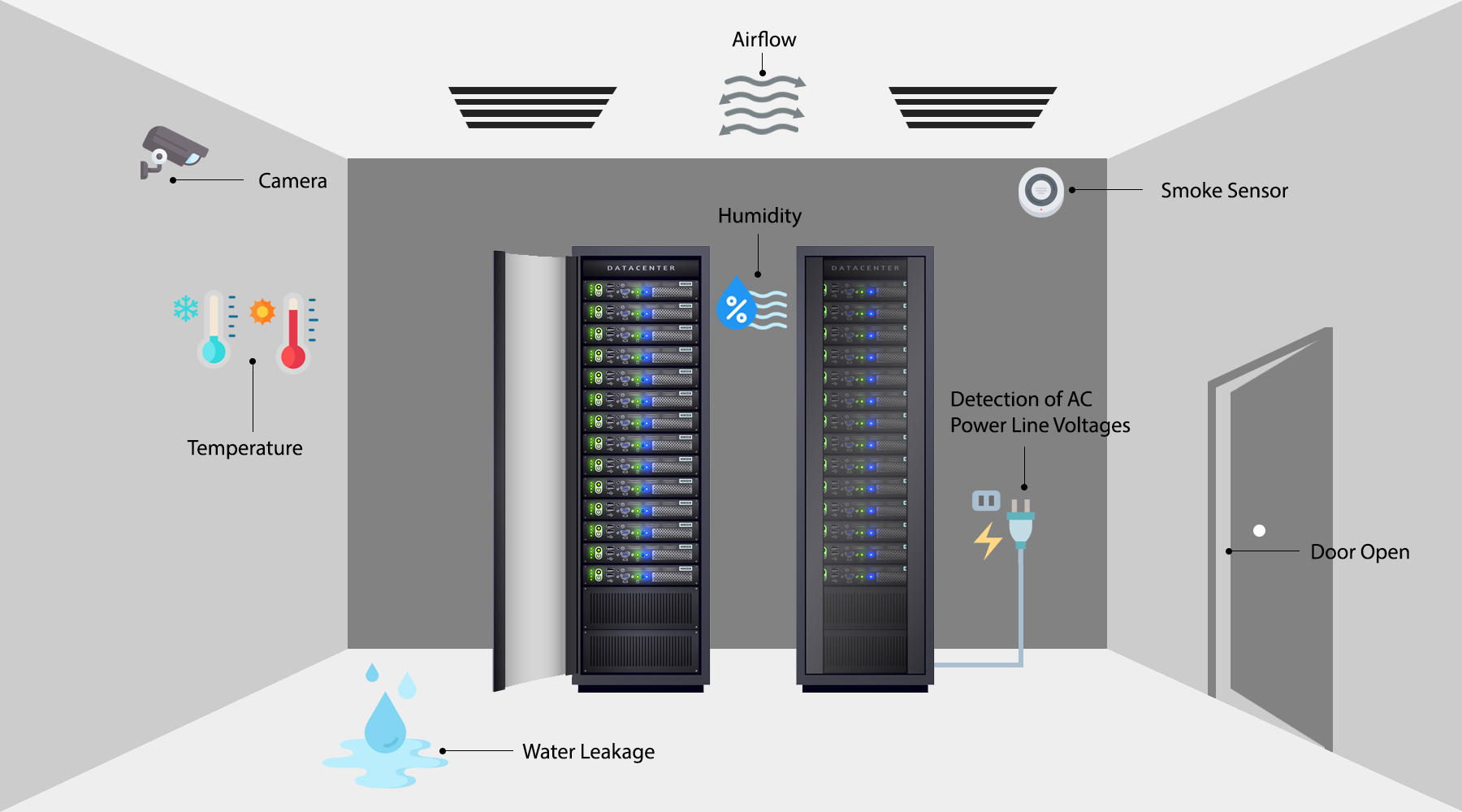

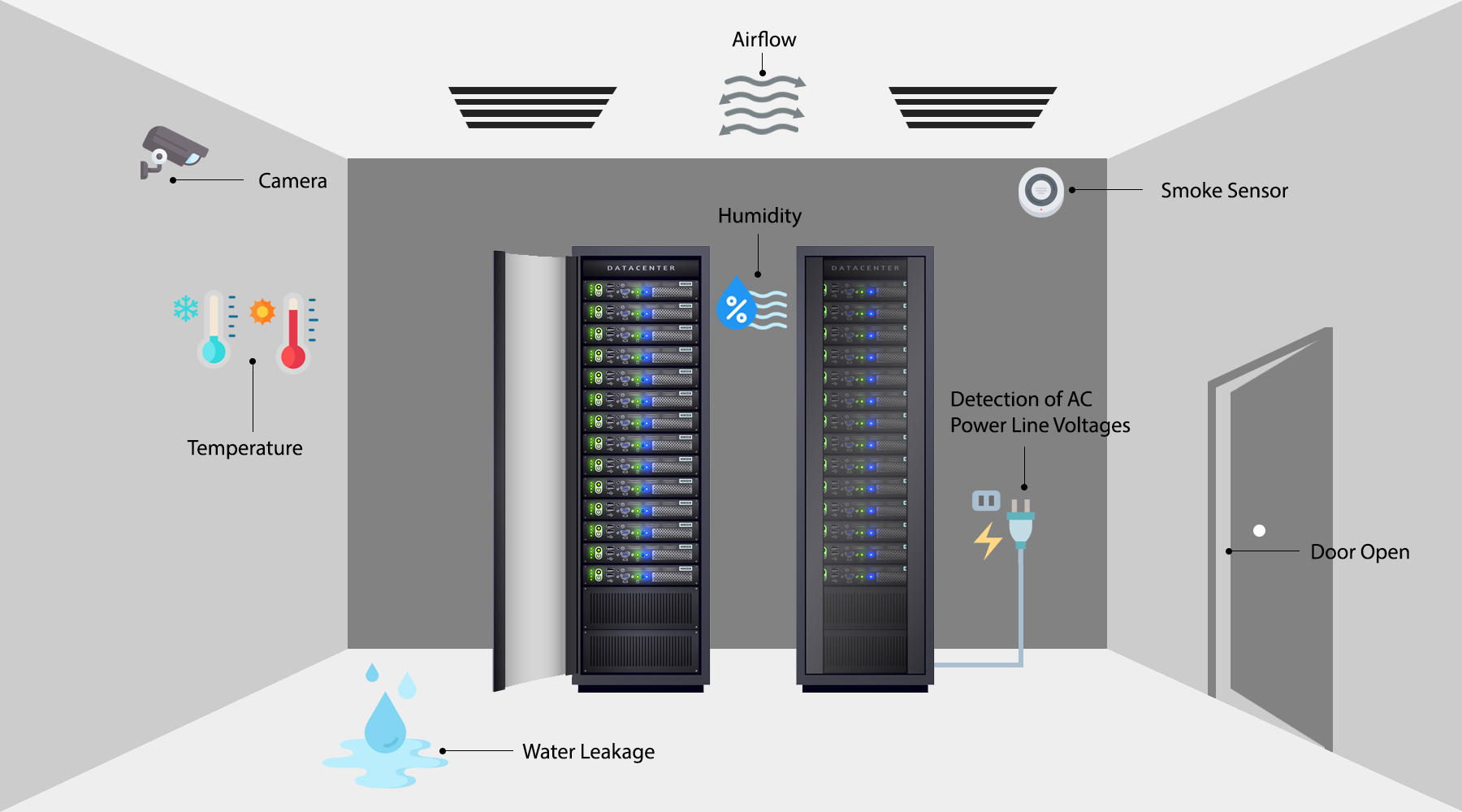

A server rack is where essential electronic data storage and processing equipment is placed. It protects your gear and serves as a housing unit. In data centers, it is where mission-critical gears are installed. But it does not provide absolute security and protection. Within this enclosure, factors such as heat, humidity, and airflow still come into play. What one needs to assure optimal conditions inside a server rack is a reliable and trusted monitoring system.

What is a Server Rack Monitoring System?

Server rack monitoring systems are devices placed into a server rack to measure the electrical and physical well-being of your data-processing gear. They collect data from within the confines of the server rack and transmit them to various displays and other monitoring media. Based on their programming, they can fix problems themselves using artificial intelligence. Or they can transmit the data collected to a display, and the technical team can step in and do the necessary repairs.

Why is it Important to Monitor my Server Racks?

The new models of data-processing gear are sturdier and more reliable than their predecessors of old. But they are not impervious to malfunction and still require monitoring. If their operational environment isn’t perfect, they still tend to bog down.

Your gear’s temperature can skyrocket and actually, melt the chips inside and take down the entire system. And if they’re running too cold, their processing power slows down and loses its efficacy.

Environmental factors that don’t instantly destroy the equipment are still capable of lessening their operational life. A server that is 10 degrees above normal won’t register an anomaly right away. It won’t set off any alarms or give off warnings. Instead, the fans will go into overdrive and burn themselves out quicker than normal. Thus, resulting to an expensive headache to have in your workplace.

photo credit: www.mesoft.ae

Types of Server Rack Monitoring Tools

There are several kinds of server rack monitoring systems that are available in the market. Choosing the perfect one begins with knowing all your choices. The following are some of the most considered:

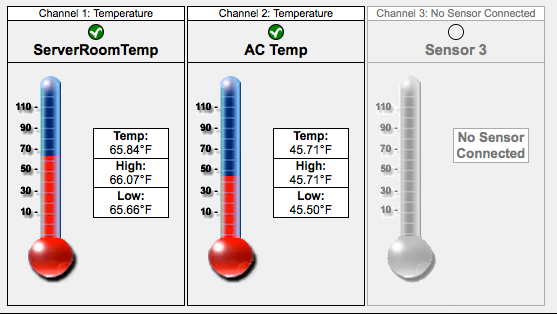

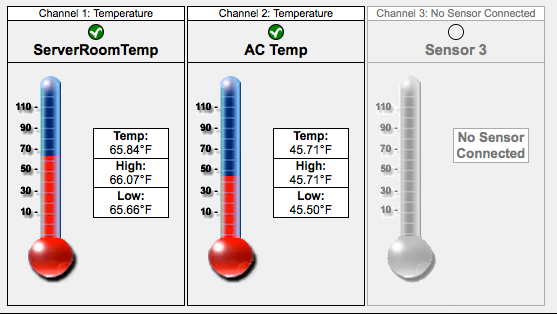

Temperature is probably the most essential factor to watch for that can cause you headaches. Monitoring the heat inside a server rack is key to the optimal operation of your gear. This server rack monitoring system comes hand in hand with the overall data center temperature monitoring system.

According to the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), the recommended number of temperature sensors per rack should range between 6 to 8. This is to fully secure and monitor temperature changes in the equipment. They should be mounted at the top, middle, and bottom and both at the front and back of the rack.

photo credit: www.mountainvistatech.com

Humidity Sensors

Whileis carefully looked at. Humidity monitoring is often taken for granted in a server rack. A big issue with IT monitoring managers is dry atmospheres that can generate the occurrence of static electricity. Too much humidity can also lead to condensation build-up. To fight ESD or electrostatic discharge. Cooling systems commonly distribute moisture into the airconditioned air. But too much water vapor in the air can lead to condensation, which can cause rust and electrical shorts. Real-time monitoring can give IT professionals precise data to strike the perfect balance. This makes humidity sensors an indispensable element in a server rack monitoring system.

AKCP has Single Port Temperature and Humidity Sensor a dual-sensor that combines temperature and humidity into one sensor. This is a piece of good news for data centers as this new prototype will free up an additional intelligent sensor port on your base unit. In situations where both temperature and humidity can be critical, you can keep up to speed on the current conditions using this sensor.

Temperature and Humidity Sensor

Air Pressure Sensors

A server rack air pressure sensor is a device that measures and controls pressurized air. For multiple purposes in engineering and data center monitoring. It allows IT monitoring managers to optimize airflow and cooling. This can easily help them apply changes if needed. The sensor identifies if the airflow and pressure are incorrect or misdirected. The system will report the gathered changes in airflow that could possibly trigger a possible HVAC malfunction or potential leakage. It also records the changes in air pressure and airflow every time the temperature shifts when used in conjunction with temperature sensors.

The AKCP Differential Air Pressure then will

monitor cabinets for pressure differential to ensure adequate airflow.

The resulting pressure differential reading will display the degree of the airflow passing through the server rack. Remember that this is not a measurement of the airflow rate, only a parallel estimate. A reduced differential pressure will display a lower airflow rate and an elevated pressure value will show a higher flow rate between high and low-pressure zones.

Contact Sensors

Contact sensors can be used to detect many different inputs such as UPS status, security systems, air conditioning status. They are connected to burglar alarms, fire alarms, or any application that requires monitoring of a system’s probe.

Vibration Detectors

For server rack vibration detector it is perfect to use the AKCP Vibration detector. It is a device designed for protection, against forced entry by a hammer, saw, and crowbar through walls, ceilings, windows, safes, and cabinets. It is used in closed-circuit alarm systems. Which triggers an alarm when vibration or a massive force hits the protected surface.

These are also known as piezoelectric sensors. And are versatile tools for the measurement of various processes. They utilize the piezoelectric effect, which measures changes in pressure, acceleration, temperature, strain, or force by converting them to an electrical charge. A vibration detector used in a server rack monitoring system can also be harnessed to identify smells and aromas in the air, by simultaneously measuring resonance and capacitance.

Vibration detectors are perfect for measuring the amount and frequency of vibration in machines or equipment in a data center. These can be used to identify and monitor specific problems like imbalances, an indicator for future malfunctions within the equipment. The range of vibration is so wide that one should always program vibration detectors o measure the maximum vibration range of your application.

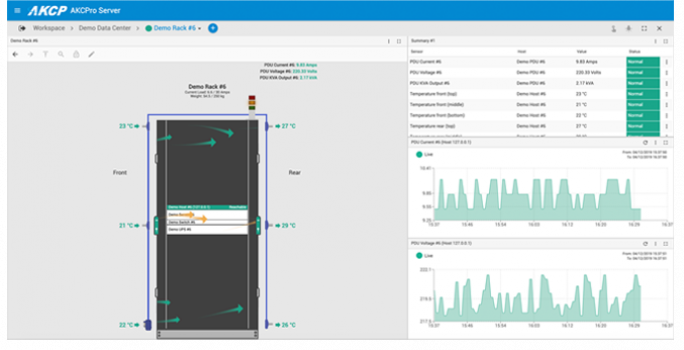

Power Monitoring

A server rack power monitor. Also known as a Power Distribution Unit (PDU). Is a device that monitors, manages, and controls power consumption to several devices in data center environments. It is capable of disseminating huge amounts of electricity. Its monitoring could be integrated with AKCP Virtual Sensors which can be logged into remotely or through the local network using. They can handle elevated power densities and can resist higher temperatures.

In an everyday data center atmosphere, the PDU is attached to an upstream Power Distribution Unit also known as a floor PDU. The purpose of this is to share power from the utility during normal operation. In the event of a power failure, an Uninterruptible Power Supply or UPS takes the place of the power load. While the generator revs up to start giving power to the data center.

How to Choose the Right Server Monitoring Tools

Selecting the perfect rack monitoring tools for a variety of eventualities is never an easy task. It is paramount to carefully monitor all factors, to give the perfect atmospheric conditions in which your data center systems can operate. However, there are also financial issues that weigh-in like how server monitoring tools can occupy space in a rack that may be utilized for IT equipment.

It’s always smart to ensure that all the important equipment in your server rack has constant monitoring gear to watch over it. Security cameras also serve additional security in the entirety of the data center. All the other monitors and detectors might serve a similar dual purpose as well. Making their utilization more cost-efficient.

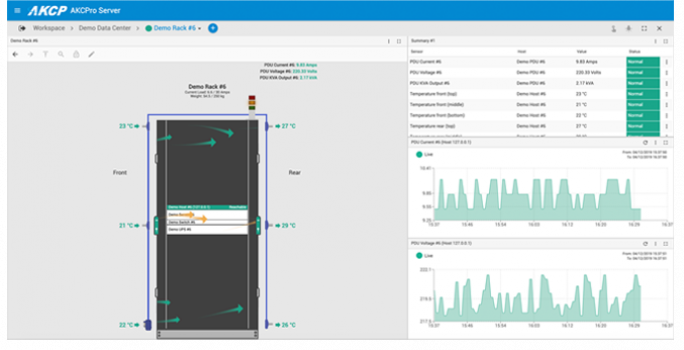

AKCPro Server is our world-class central monitoring and management software. Suitable for a wide range of monitoring applications. All deployed AKCP base units and attached sensors can be configured and monitored from

AKCPro Server (APS). Base units communicate with the server through your wired local network (LAN) or wide area network (WAN). Remote sites with no wired network send data to the server through the cellular data network.

AKCPro Server can also be accessed on all types of mobile platforms. Whether it be your smartphone, tablet, or PC you view the systems UI through the HTML5 user interface on any web browser.

AKCPro Server

Conclusion

We have now shown you what server rack monitoring systems are and their importance in the day-to-day operations of your data center. Remember this safety measures to safeguard the working environment of your servers is worth every penny if it guarantees your business efficiency. Simple precautions such as temperature or humidity reading can save you thousands of maintenance fees. Monitoring is not just to save your pocket but also your reputation as a reliable data center.