- Underfloor Air Delivery

- Structural Strength

- Airflow

- Leakage

Airflow And Cooling Management

Overhead air ducts for cold air distribution tend to be limited. The delivery of chilled air under a raised floor is easier because arranging the perforated floor tiles is all that is required to change the air distribution. Raised floors also offer more room for cabling which eliminates the additional manpower and infrastructure that overhead requires.

Regardless of the many advantages of raised floors, still accounts for many data center cooling problems. Uneven air pressure and spotty air delivery are commonly caused by air turbulence. Some buildings also do not have the slab-to-slab clearance for the height requirements of raised floor type data center.

The space under the raised floor is used for cabling which becomes an obstruction for air cooling. Therefore, proving a raised floor design is not fit to accommodate higher-density rack deployment (8kW–10kW per rack and up).

Levelness & Load Capacity

For poured concrete, load capacity will not be an issue. However, it’s a concern for facilities with raised floors and structural ramps. Here are the three types of loads to consider:

-

Point Load

Most racks sit on four feet or casters. The point load is the weight of a rack on any one of these four points. For example, a Sun Fire 15K server rack is 2200 pounds with four casters, so the load distribution is 550 pounds per caster. A floor tile must have a higher than 550- pound point load, which means that a 1-inch square of the tile must be able to support 550 pounds without deflection of more than 2 mm.

-

Static Load

The static load is the additive point load on a tile. If you have two racks, each with a 400-pound point load, and each rack has one caster on a tile, this tile will have an 800-pound static load. The tile must be rated for at least an 800-pound static load.

-

Rolling Load

The rolling load should be close to the static load and is usually only applicable to perforated tiles. Since it is possible that you might use your cool aisle to also serve as an aisle to move equipment, the perforated tiles will need to support the weight of two-point loads of a rack as they are rolled along the aisle. If the perforated tiles cannot accommodate this load, you would have to temporarily replace them with solid tiles. This would prohibit proper airflow from the cool aisle and add work every time you need to move a rack.

Ramp

Ramps no doubt take such great space in the data center. Americans with Disabilities Act (ADA) has a requirement of a 1:12 slope, this suggests that there must be one foot of length for every inch of floor height.

Evaluating Raised Floors and Panels

There are many types of raised floors. In the early days, they were made of weak materials such as wood or hollow steel and they can actually support the cabinets and equipment back then. However, the modern raised floors are now made of cement-filled steel or cast aluminum to accommodate the heavier equipment and cabinets of today’s data centers.

It’s not easy to just select which panel to use for a data center. Panels are usually marketed according to their “concentrated load” ratings. This rating is the maximum load that can be applied to the weakest point of the square inch of the tile without deforming it by more than a specified amount.

Types of Raised Floor Material

-

Woodcore Floor

This is made of high-density composite wood core glue and encased in hot-dipped galvanized formed steel sheets. These panels have a class A flame spread rating and provide excellent rigidity, durability, and acoustic performance. It’s also economical, durable, rolling load performance, fire safety, versatile support system, and quiet, galvanized shell to prevent zinc whiskers.

-

All-Steel Raised Floor

Made from a high-quality steel plate that has been stamped, welded, and injected with high-strength lightweight materials. Its surface is epoxy and electrostatically painted. It has excellent rolling load performance, is lightweight, for ease of handling, has excellent design load performance, epoxy finish for lifetime protection. Also, the grounding and electrical continuity of our All-Steel access floor are outstanding.

-

Concore Floor

This is an epoxy finish floor for lifetime protection, solid and quiet, superior ultimate load performance, completely non-combustible, and interchangeable panel strengths.

-

Aluminum Raised Floor

This is the most expensive one of 4 types of raised floor panels. Because there are many advantages to using it: lightweight for ease of handling, will not be deformed by water immersion and moisture, and will not corrode, so its service life is long. Contains no ferrous materials to disrupt magnetic fields, and has excellent rolling load performance. The aluminum access floor is available in a wide selection of conductive, static-dissipative coverings or coatings. What’s more, Its’ perforated panels and grates provide optimum laminar airflow.

Raised Floor Maintenance and Cleaning

Photo credit: www.facilityindia.com

To protect data center investment in this kind of environment, proper maintenance must always be followed. Below are the proper raised floor maintenance and care:

- Dust or vacuum the floor daily.

- Damp-mop only with warm water and mild multipurpose ammoniated floor cleaner. DO NOT use excessive water, Large amounts of water can weaken adhesive and cause de-lamination.

- Do not use abrasives, scrapers, or strong solvents to remove stains. DO NOT use the wax seal on the laminate surface.

- Have your Raised Flooring System professionally inspected and cleaned by a professional raised access floor maintenance technician once a year.

- Vacuum under-structure and subfloor at least once a year.

- Clean air flow and perforated panels twice a year.

- Vacuum carpet panels twice a week with a static dissipating vacuum.

- Clean carpet Raised Flooring System with dry foam/powders at least twice a year.

- Utilize runners and mats in high traffic areas.

Security

This is particularly a concern for co-location facilities that accommodate multiple customers at the same time. Some cabinets that store sensitive and critical data are installed inside a cage unit. A ceiling to the raised floor to concrete slab floor partition separates the cabinet from the other cabinets in the data hall.

Monitoring Airflow In A Raised Floor Data Center

Monitoring solutions with alarm and notification capabilities must be introduced. This is to assess the effectiveness and efficiency of cooling and containment systems. Datacenter operators can fine-tune control by measuring temperatures at the rack level. Ensuring that they remain within the required temperature without overcooling space. Monitoring rack-level temperatures can also help to ensure that floor pressure is adequate. This means that the chosen airflow panels are delivering enough cold air to server rack inlets. An alarm threshold is set so that a rise in temperature may be detected and responded to. Thus, preventing the loss of cooling at the local level, which can be caused by a variety of circumstances.

Datacenter operators can also use improved monitoring tools. Monitoring differential pressure between the floor plenum and the contained aisle can be advantageous in a contained aisle. Without sufficient pressure, enough cold air may not reach the cold lane, or warm air may leak back into the enclosed cold aisle, reducing cooling and efficiency.

AKCP Wireless Sensor and Gateway

Wireless Cabinet Sensor

The W-CAS has a cabinet thermal map for detecting hot spots, a differential pressure sensor for airflow measurement, and two dry contact inputs for door security sensors. Data is captured and delivered to one of our wireless sensor gateways.

Thermal Maps

Cabinet thermal maps consist of 2 strings of 3x Temp and 1x Hum sensor. Monitor the temperature at the front and rear of the cabinet, top, middle, and bottom. The △T value, front to rear temperature differential is calculated and displayed with animated arrows in AKCPro Server cabinet rack map views.

Differential Pressure

To prevent air from mingling from the hot and cold aisles, there should always be positive pressure at the entrance of the cabinet. Because air goes from high to low-pressure zones, it’s critical to ensure that the front of the cabinet has higher pressure and the back has lower pressure for efficient cooling.

Door Contacts

I/O dry contact inputs can be used to monitor the front and rear doors of the cabinet, or alternatively alarm outputs from a UPS or other rack-mounted equipment.

Rack Maps and Containment Views

On AKCPro Server dedicated rack maps displaying W-CAS sensor data can be configured to give a visual representation of each rack in your data center. If you are running a hot/cold aisle containment, then containment views can also be configured to give a sectional view of your racks and containment aisles.

When selecting a monitoring system, several factors should be taken into consideration, including the ease of deployment, ease of integration to DCIM systems, and the flexibility to add additional types of sensors to the chosen system.

AKCPro Server

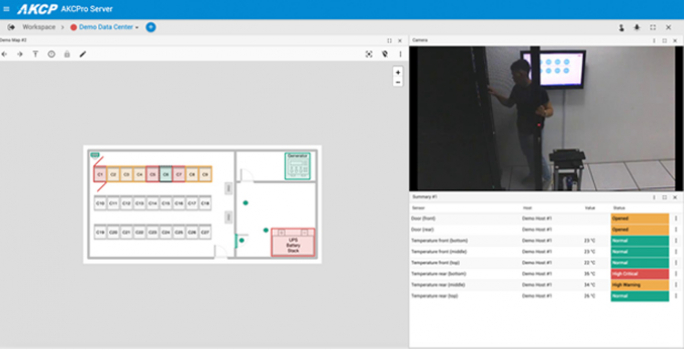

AKCPro Server

AKCPro Server is our world-class central monitoring and management software. Suitable for a wide range of monitoring applications. Free to use for all AKCP devices. Monitor your infrastructure, whether it be a single building or remote sites over a wide geographic area. Integrate third-party devices with, Modbus, SNMP, and ONVIF compatible IP cameras.

All deployed AKCP base units and attached sensors can be configured and monitored from AKCPro Server (APS). Base units communicate with the server through your wired local network (LAN) or wide area network (WAN). Remote sites with no wired network send data to the server through the cellular data network

AKCPro Server can be accessed on your smartphone, tablet, or PC. Access is operating system independent, viewable through the HTML5 user interface on any web browser