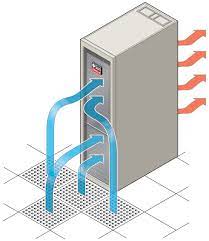

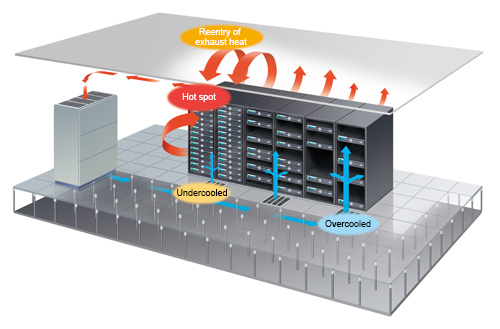

The more power a server consumes, the more cooling it needs. This is why air conditioning systems are the biggest consumer of energy in many data centers. When heat builds up because the cooling system is not capable of keeping up hotspots result which can cause servers to malfunction. It is therefore important to ensure that server rack airflow is capable of carrying away the heat generated by the server. This article will look at solutions to improve energy efficiency through improving server rack airflow.

Server Racks and Network Cabinet Designs

Photo Credit: campustechnology.com

A standard design for a server rack is a four-post frame to which side panels, and front and rear doors are attached. The unvented side panels are usually removable. The front door can be customized into various designs such as perforated for ventilation or glass. This is also an option for the rear door.

The front door of the rack could be installed with an RFID lock handle. It is also recommended to install monitoring devices within the server room environment. They should be deployed in both the room and within the racks to monitor the thermal conditions of the server room.

Custom Server Racks

In today’s industry, data centers can now customize their server racks and make alterations that may fit the facility design, r something that could be more practical to fit the cooling strategy in use. Customization ranges from including liquid-cooled panel doors, built-in air conditioning units, overhead metal returns, or the use of a cold or hot-aisle arrangement. The standard rack has an IP rating of 20 but through customization, it can be increased to IP54 or higher depends on the requirement of the data center.

Rack-Level Air Flow Strategy

All IT equipment must have a proper supply of cool air coming in the front of the rack. This strategy ensures that

Photo Credit: www.azbil.com

the air passes through all equipment within the rack. Any gaps should be sealed as they serve as an opportunity for the air to bypass the servers, wasting cooling energy. This is the purpose of front blanking panels. A blanking panel is a piece of plastic or metal that goes into an empty spot in the rack to prevent cool air to pass through it or hot air to slip back inside the rack.

A well-implemented server rack airflow plan has many benefits in terms of energy efficiency. It reduces demand for local air conditioners saving energy and costs. Having effective server rack airflow management, you won’t need to think about hotspots and their consequences in your data center. It also allows you to ensure no areas are overcooled, wasting cooling energy.

Server Rack Air Flow Checklist

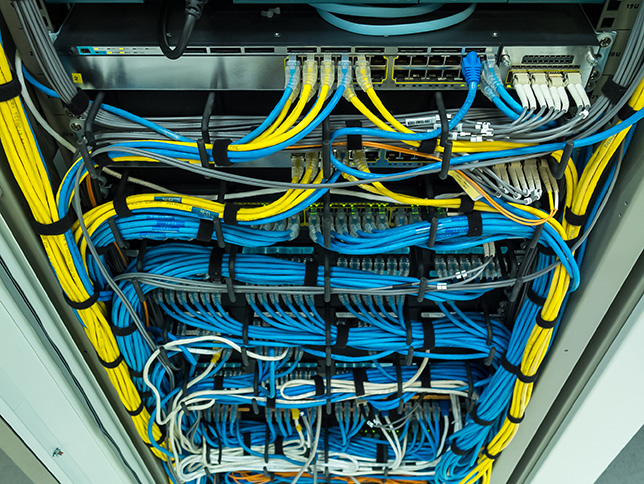

Photo Credits: www.accu-tech.com

However small an open space or unsealed space is, it can still reduce the server rack airflow efficiency. Managing the server rack airflow mainly focuses on getting the air past all the equipment then straight to the exhaust channel. Small openings, or missing blanking panels are not always a problem if air pressures and airflow management is done correctly. Here are few recommendations to consider:

- Front Door Design

Rack front doors, as mentioned earlier, can be customized depends on the requirement of the data center. However, it is important to take note that the front door also affects the design of the cooling system and the thermal dynamics of the rack.

The door provides the access to the equipment within the rack. For security, access can be connected to the building access control system or it can have its locally installed security system.

- Rack Height Spacing

It is important to use a suitable sized and fixed server cabinet. This ensures that each available ‘U’ is used or covered with a blanking plate and this is to prevent to have any air gaps. The blanking plates, of course, should be in a suitable size as well. The more blanking plates are used the more the gap and server rack airflow efficiency issues are compounded.

- Rack Equipment Layout

Laying out equipment in the rack requires the utmost care. Take time to know which equipment generates the most heat and where to place them. One thing that should be on top consideration is the UPS systems. If the batteries are valve-regulated lead-acid (VRLA) type they require 20-25°C ambient temperature.

- Side Panels and Rails

Bypass airflow happens when the cooled air is returned to the air cooling unit without passing the IT equipment. Operators should make sure that the spaces between the side rails, the equipment they are supporting, and the backside panels are sealed. As these spaces provide an opportunity for bypass airflow.

- Top of Rack

Ensuring a good airflow around the top fan tray of the rack is important to avoid any potential airflow infringement that could reduce the overall cooling effect.

- Rear Doors

Rear doors are usually overlooked as it is only regarded as access to terminals and power connections. But in truth, this area is where the hot air is channeled and exhausted for return to the cooling unit. Mixing hot air and cold air must be avoided at all times to ensure optimal efficiency. Rear doors must be as fitted as everything else to ensure the exhausted hot air’s path back to the cooling unit.

- Temperature Monitoring

Installing a temperature monitoring system within the server rack is the best strategy. Deploy the temperature sensors at three levels, as per ASHRAE, from the top, middle, and bottom sections at the front and rear of the racks. Choose a suitable monitoring system that offers 24/7 real-time monitoring and alarm notifications. Monitoring solutions could also be expandable or include other aspects like smoke and water detection.

Server Room Airflow Monitoring with AKCP

Server Rack Airflow and Thermal Mapping for IT Cabinets

The Cabinet Analysis Sensor (CAS) features a cabinet thermal map for detecting hot spots and a differential pressure sensor for analysis of airflow. Monitor up to 16 cabinets from a single IP address with the sensorProbeX+ base units. The Wireless Cabinet Analysis Sensor is also available using our Wireless Tunnel™ Technology.

Differential Temperature (△T)

AKCP Cabinet Analysis Sensor

Cabinet thermal maps consist of 2 strings of 3x Temp and 1x Hum sensor. Monitor the temperature at the front and rear of the cabinet, top, middle, and bottom. The △T value, front to rear temperature differential is calculated and displayed with animated arrows in AKCPro Server cabinet rack map views.

Differential Pressure (△D)

There should always be a positive pressure at the front of the cabinet, to ensure that air from hot and cold aisles is not mixing. Air travels from areas of high pressure to low pressure, it is imperative for efficient cooling to check that there is higher pressure at the front of the cabinet and lower pressure at the rear.

Rack Maps and Containment Views

With an L-DCIM or PC with AKCPro Server installed, dedicated rack maps displaying Cabinet Analysis Sensor data can be configured to give a visual representation of each rack in your data center. If you are running a hot/cold aisle containment, then containment views can also be configured to give a sectional view of your racks and containment aisles.

Additional Server Room Monitoring from AKCP

AKCP Water and smoke Detectors

Water Detection

Ideal for detecting water leaks in hard-to-see areas, such as under-raised floors and false ceilings. The Locate Rope Water sensor will give you a precise location of the water leak so you can respond promptly to protect your enterprise resources from water damage.

This sensor comes fully assembled and includes the rope portion that is the water sensing cable, the non-sensing cable, and the main sensing module. The sensing cable can be pre-ordered from a 10-foot minimum to any custom run length of up to 160 feet. The non-sensing cable comes in a standard 20-foot run length.

The specific location of water along the rope can be used to trigger alerts like e-mail, SMS, phone calls, and SNMP traps. The sensor has its own SNMP OID so that it can be monitored over the network using any Network Management System.

Smoke Detector

Fire detection in its early stage is very important. There are many smart fire detectors in the market now that can adapt or cope up with various types and layouts of server rooms and provides accurate and very early warning of fire.

AKCP has designed a smoke sensor specifically for use with its securityProbe product line. These smoke detectors are easy to install and configure and can be used in conjunction with all other AKCP alerting and monitoring features.

For server room, monitoring inquiries message us at [email protected]

Reference Links:

https://www.upsite.com/blog/rack-airflow-management-how-sealing-gaps-leads-to-energy-savings/