When designing a data center, you’ll want to consider how your server racks should be organized. Blanking Panels are a piece of equipment in IT racks that many people ignore. It is usually a piece of plastic or metal that is inserted into an empty rack space, available in 1U or 2U configurations. Sometimes with brushes to bring cables from front to rear. They will remain in place until a new server or another piece of equipment is installed in its place.

Advantages of Blanking Panels

Proper Server Rack Airflow

Photo credit: www.stulz.de

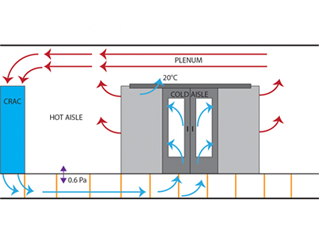

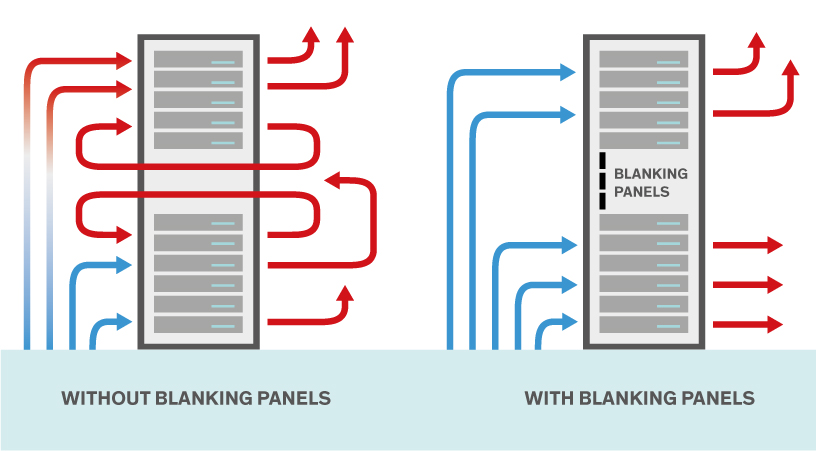

Modern server racks are designed to ensure that air flows evenly, allowing for effective cooling of the servers and rack-mounted equipment. This design, on the other hand, only works when all of the slots in the server are occupied. If there are empty slots you can have wasted cooling through bypass airflow, and recirculation of hot air from the rear to the front air intake.

-

Creating ‘Dead’ Spots

If the rack has an open U, the airflow, taking the path of least resistance may flow through the open U in preference to through the servers. This can result in ‘dead’ regions where the air doesn’t move or flow slowly. As a result, a hotspot develops, which may cause equipment issues.

-

Air Pulling from the Opposite Side

The opening may allow air to flow from one side of the rack to the other. Hot air, expelled at the rear of the rack can recirculate back to the front, decreasing the effectiveness of the cooling.

-

The ‘Tornado’ Effect

This occurs when air collides with an unanticipated opening and blows in the other direction resulting in an area in the rack where the air spins in place instead of blowing out. This causes the cooling effects to be disrupted.

Essential for Server Rack Cooling

As the preceding steps demonstrate, good airflow is essential for cooling. The air will go exactly where it should when you install your blanking panels. This keeps the entire rack at the right temperature while the equipment is running. One of the most significant advantages of server racks, in general, is a well-designed cooling system. Getting the most out of this benefit is definitely worth the small investment in time and money required to purchase and install blanking panels.

Cleaner Rack

Blanking panels that are properly placed will also help to decrease dust problems. While the air in a data center should be purified, it is nearly impossible to eliminate all dust. To prevent dust from getting into your servers and other equipment, ensure the dust is blown out of the server rack as quickly as possible. The blanking panels will assist in this by ensuring that the airflow is not disrupted and moves as intended.

Improved Aesthetics

Photo Credit: www.energystar.gov

The first thing people will notice about a server rack with blanking panels is how much nicer it appears than a rack with only apertures. While appearances aren’t the most significant factor when it comes to storing computer equipment, they are worth mentioning. For most businesses, ensuring that the equipment looks nice will help to wow clients. For others, it will merely demonstrate that the racks are appropriately configured for efficient airflow, which is something that all IT experts understand is critical.

Increasing Need for Blanking Panels

The use of blanking panels has been recommended by the IT sector since the early 2000s. The benefits of blanking panels are recognized by IT equipment makers, who educate users on the necessity to utilize them.”

“Increasing computing density has elevated IT equipment intake temperatures and increased failure rates, raising awareness about the necessity of effective and efficient conditioned airflow management in computer rooms,” according to Upsite, a major maker of blanking panels.

The American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE), as well as most major server and storage manufacturers, recognize the severity of the power consumption used to cool data centers and recommend that blanking panels be installed in unused rack space to maximize and improve the room’s hot aisle/cold aisle airflow containment system.

Features of Blanking Panels

Plastic panels are affordable, quick to install, allow good control, and aid ventilation, but they are less durable overall. While metal panels appear to be more solid they are costly and more difficult to install. For these reasons, it appears that metal panels have lost favor, and they should only be used if spare RUs are expected to stay empty for the foreseeable future.

Some of the panels must be screwed into place. Others, referred to as tool-less solutions, can snap into position on the rack.

How to Properly Use Rack Blanking Panels?

Blanking panels should be used on all empty rack spaces in data centers, according to the study’s findings. It’s not just for big chasms. Because these plates exist in a variety of sizes, even the tiniest gap can be filled with a custom-sized panel.

Some individuals believe it is preferable to leave gaps between servers so that they do not overheat. It is not advised for Dell. Stacking servers closer together is a better strategy. The air is propelled through the openings by the pressure. According to a study, leaks between blanking panels have a greater impact. Even gaps of the same size allow air to move short distances, causing problems for nearby servers. When compared to a server farm, where servers are stacked on top of each other. The air will only travel past them, and the devices will not be heated.

Blanking panels might take a long time to install. However, its energy-saving potential outweighs the cost.

The biggest sizes typically available are 6U.

AKCP Blanking Panels

Wireless Monitoring with AKCP

AKCP Wireless Cabinet Analysis Sensor

All In One Wireless Cabinet Sensor

The Wireless Cabinet Analysis Sensor (W-CAS) features a cabinet thermal map for detecting hot spots, a differential pressure sensor for analysis of airflow, and 2x dry contact inputs for door security sensors. Powered by USB, or 4x AA rechargeable batteries and using AKCP Wireless Wall Penetrating Technology data is collected and sent to one of our wireless sensor gateways. A wired version of the W-CAS is also available for use with the sensorProbeX+ base units.

Thermal Maps

Cabinet thermal maps consist of 2 strings of 3x Temp and 1x Hum sensor. Monitor the temperature at the front and rear of the cabinet, top, middle, and bottom. The △T value, front to rear temperature differential is calculated and displayed with animated arrows in AKCPro Server cabinet rack map views.

Differential Pressure

There should always be a positive pressure at the front of the cabinet, to ensure that air from hot and cold aisles is not mixing. As air travels from areas of high pressure to low pressure, it is imperative for efficient cooling to check that there is higher pressure at the front of the cabinet and lower pressure at the rear.

Door Contacts

I/O dry contact inputs can be used to monitor the front and rear doors of the cabinet, or alternatively alarm outputs from a UPS or other rack-mounted equipment.

Rack Maps and Containment Views

The L-DCIM runs AKCPro Server. Dedicated rack maps displaying W-CAS sensor data can be configured to give a visual representation of each rack in your data center. If you are running a hot/cold aisle containment, then containment views can also be configured to give a sectional view of your racks and containment aisles.