The energy consumption of a data center is a significant resource that should not be overlooked. IT equipment consumes most of the energy resources. This power consumption through the servers is dissipated as heat. For efficient operation and maximum uptime, the cooling system must remove this waste heat.

The current trend of increasing IT densities brings both opportunities and risks. Higher IT densities result in higher energy consumption. Despite the state-of-the-art infrastructure, it is inevitable to run into some roadblocks along the way. The biggest of it all is downtime due to unmanaged temperature conditions.

Optimization of Cooling System

One way to reduce the risk of data center downtime is cooling optimization.

The concept of cooling optimization derives from the notion of improving energy efficiency. The process entails making necessary adjustments to yield better energy levels. Recalibrating system controls is part of the step to optimize the cooling facility. Add to that, many correlated benefits can arise from improved energy efficiency.

- Reduced Operating Costs

- Improve Cooling Capacity

- Improve IT Reliability

- Save Capital Expenditure

Cooling optimization is an iterative process. Because a data center runs continuously, each day is a different case scenario. However, adapting to these different cases is the main objective of cooling optimization. The initial step in optimization is an adjustment of controls. Once controls are in proper alignment, the system can equalize. On the other hand, Datacenter managers can deal with forthcoming cases by making additional adjustments as they come along.

Why Is It Essential To Conduct Cooling Optimization?

Optimization can be done in any significant change in a room. It is primarily a necessary process in a data center that is steadily evolving. To accommodate better operational outputs, data centers will invest in equipment upgrades and layout changes. Such change initiates the need for optimization.

-

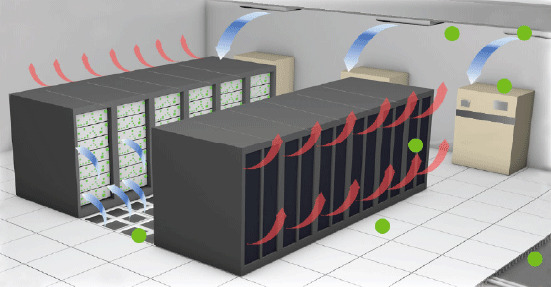

Airflow Management Improvement

Photo Credit: www.stulz.it

In principle, airflow management is part and parcel of a data center operation. However, additional investment in airflow management is considered an expense already. Optimization is utilized as a form of self-check.

Any significant improvement, be it an IT installation or removal, calls for a reevaluation of system controls. Cooling optimization necessitates a process in which controls are evaluated to a level that can assure efficient output.

In the end, efficiency is not something one can buy. It requires sound management.

-

Improve Data Center Metrics

Cooling optimization tackles two critical metrics in a data center: Power Usage Effectiveness (PUE) and Rack Cooling Index (RCI). The ratio between total facility energy over the IT load constitutes the PUE threshold. A higher PUE result would mean a very inefficient cooling system.

On the other hand, RCI accounts for the index of the data center cooling system effectiveness in managing the rack air temperature intake. Once the component’s air temperature goes beyond the recommended range, the cooling process is deemed inefficient.

Hence, optimization is one way to improve metric outputs.

Five Steps To Optimize Your Data Center

In a cooling system, heat should be the most common enemy. Facilitating a colder parameter will raise better temperature conditions and airflow.

-

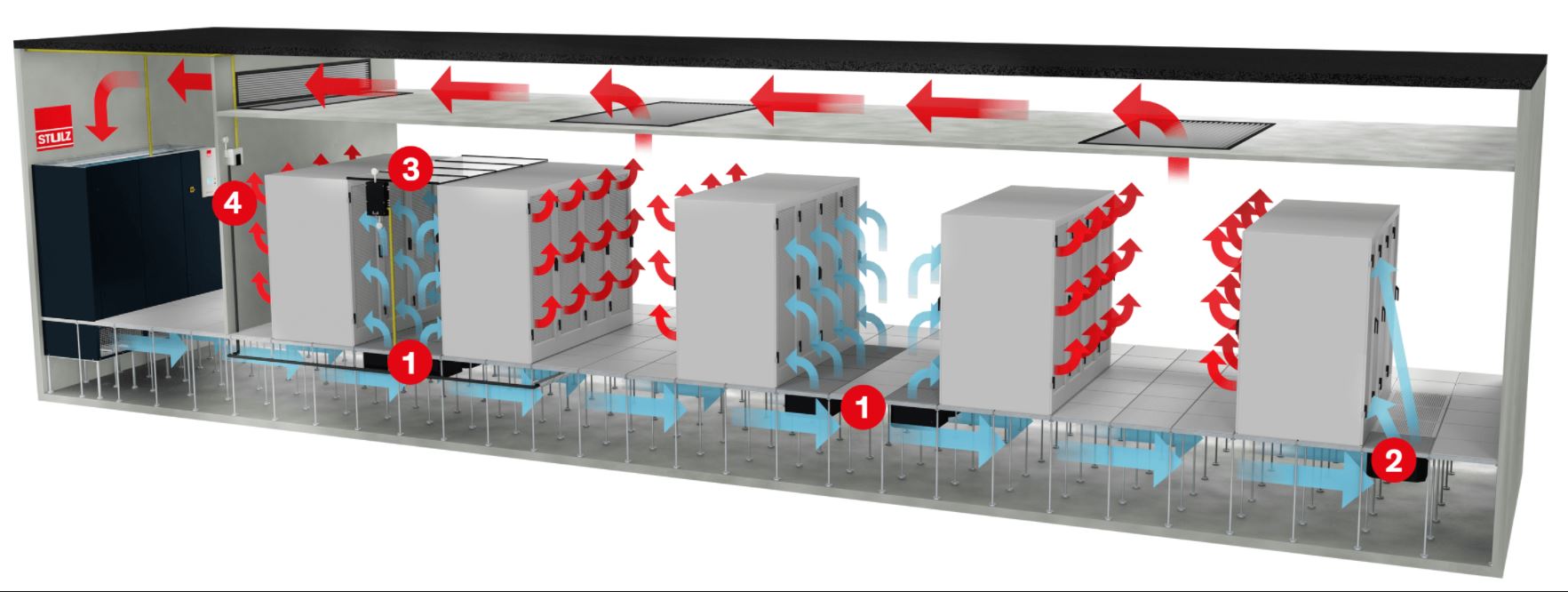

Separate Airflow

The common occurrence in server racks is the need to contain incoming air simultaneous to exit air. In line with this, better containment measures are needed. A better containment process will facilitate hotter air. Which, in turn, will be more efficient in rejecting heat.

-

Temperature Control

There is a recommended temperature range to ensure high-efficiency returns. One indicator that influences this is temperature. It is best not to be complacent but also not to overutilize your server fans. You run the risk of higher energy consumption for ramped-up server fans. A standard range of 65°F to 80°F is recommended to optimize your temperature conditions.

-

Adjust IT Load

The problem with data center upgrades is the increased fan requirement. They are needed to fans more air to the facility. But this also accounts for higher electricity damage. Using a variable capacity system will negate this disadvantage. The variable capacity system will adjust depending on the IT load. As such, no energy is wasted. There is sufficient energy allocation to fan the system but also limits reliability problems because of insufficient air.

-

Determine Controls

A regular control check is a must in data center operation. For many, a comprehensive monitoring plan is advised to get real-time parameter checks. These controls will reduce the chances of fluctuating parameters. A constant temperature tracking in the servers and aisles is a good practice. A consistent review of cooling equipment can also sustain the capacity of the unit to repel heat.

-

Operational Economics

Often, as much as we want to get the best optimization technologies, hefty investments are inevitable. However, one should not go the extra mile if there are good alternatives around. A mechanical refrigerator is excellent, but outside air can also function to reject heat. This type of economic consideration is crucial to maintain efficiency without breaking the bank.

Optimization Starts From Design

Photo Credit: industryarcblog.com

The efforts needed to optimize a place are extensive. Sometimes, before getting on the ground running, a comprehensive plan is essential. A plan with good design functionality can do so much. This also limits the additional cost to upgrade or renovate. Cooling designs are ideal steps to optimize the location of cooling units.

-

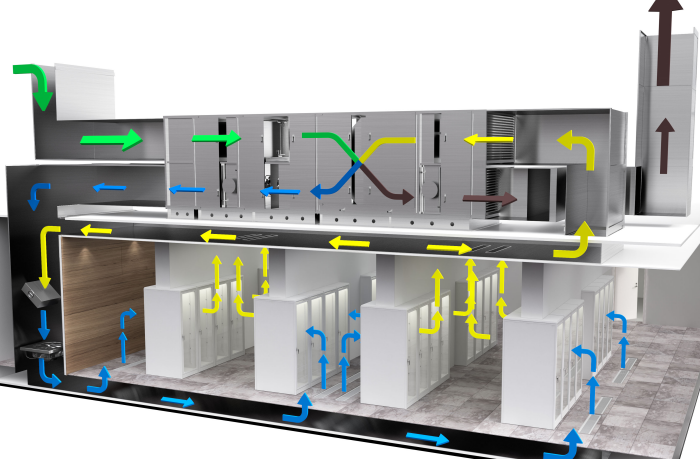

Enclosure Design

Often neglected during the initiation phase, enclosure design is the most obvious step before everything. Evaluating cooling requirements to ensure that proper materials are used can go a long way. Determining efficient thermal layout and electrical equipment used will allow better cooling levels in the long run.

-

Optimizing Airflow

Airflow is already a crucial variable in an optimization process. In the enclosure design phase, it is the supplementary parts that need planning. When those parts are already decided, they should complement enclosure cooling designs. These complementary dynamics will minimize air resistance to ensure natural paths are present for air intake or outtake.

-

Enclosure Sealing

Air leaks cause hot spots in the facility. These are tiny air openings wherein air can pass through. Not only will it undermine your heat rejection, but it will also cause dirt, debris, and moisture that are environmental factors affecting your IT lifespan. Cable openings or conduit entry points are often the pathways for air leaks. It is vital to take note of these sources and initiate proper sealing actions.

-

Equipment Layout

Arranging equipment should account for the thermal accumulation in the facility. There is also other IT equipment that requires a particular location. The likes of VFD will need a clear space below to allow air intake. Mounting them in heat-producing equipment is dangerous. Heat generation is a crucial indicator in equipment arrangement. In theory, heat-generating equipment should not be close together. Server racks also require air pathways for better airflow.

-

Limiting External Heat Sources

Total heat load is affected by additional heat sources, more often external. The electrical enclosure should be shaded and installed in a cool, dry place. Exposure to the sun will aggravate heat loads.

Optimization Through Monitoring

Controls are best adjusted and maintained with regular monitoring. In the case of cooling optimization in a data center, these controls are easily checked through monitoring solutions.

AKCP Wireless Tunnel System

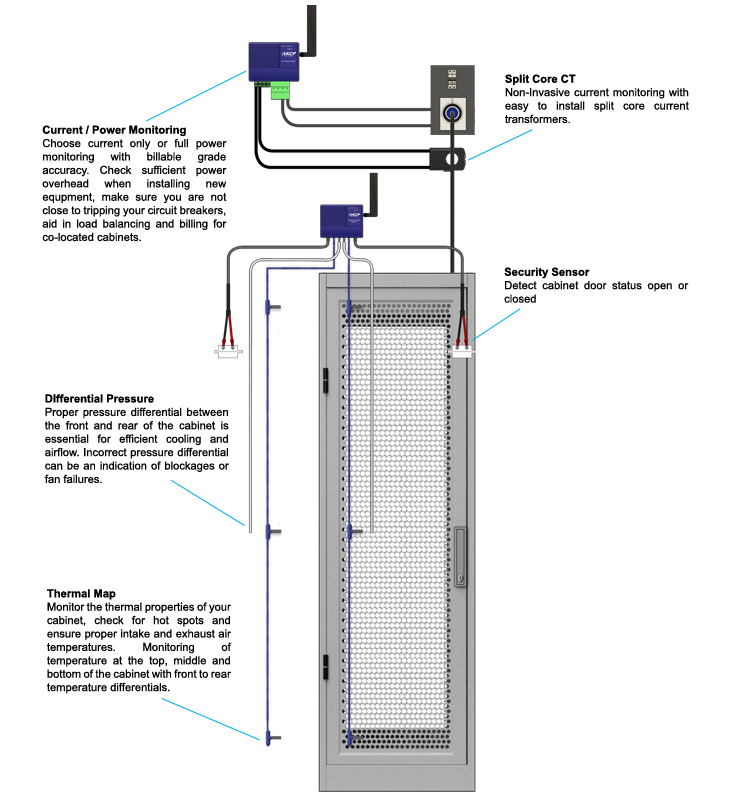

AKCP Monitoring Rack+

Datacenter monitoring is streamlined through wireless sensors from AKCP. It is designed for rapid deployment, easy install that provides long-range, high penetration sensor communication. AKCP can also tune the network for specific use cases and end-user requirements. AKCP wireless technology can offer the following features for an end-to-end monitoring relay:

- Message Acknowledgment

- Instant Threshold Broadcasting

- Bandwidth Utilization

AKCP Rack+ Data Center Sensors

One specific technology that can address data center needs is intelligent solutions for computer cabinets. This feature allows the installation of any AKCP sensors to your cabinet to build an intelligent rack solution. Connected to sensorProbe+ base unit, it has comprehensive monitoring output such as:

- Thermal Mapping

- Differential Pressure

- Current/Power

As a whole, AKCP’s data center monitoring allows an end-to-end check for better data center uptime. Specifically, the monitoring checks are the best reference for cooling optimization.

Generating Efficiency Gains From Cooling Optimization

The cooling system consumes energy by 37% – 40% in a data center operation. While there are several strategies to employ to save energy, optimization focuses on efficiency as a whole. This is why the readjustment of controls is integral in its process. What better way to adjust and sustain sound system controls than a thorough monitoring plan?

Cooling optimization is an iterative process. So is monitoring. Both go hand in hand to better a data center’s operational value. Every significant data center change is an opportunity to refine cooling optimization. It is also an opportunity to establish the best control threshold. In this way, efficiency gains will just be a regular part of the trade.

Reference Links:

https://www.youtube.com/watch?v=iMkk5UTtu_c

https://thermal-edge.com/6-ways-to-optimize-your-cooling-design/

https://edge.siriuscom.com/infrastructure-operations/5-steps-to-optimizing-your-data-center-cooling

Mukaffi, A. I., Arief, R. F., Hendradjit, W., & Romadhon, R. (2017). Optimization of Cooling System for Data Center (Vol. 170 ( 2017 ), pp. 552-557, Rep.).