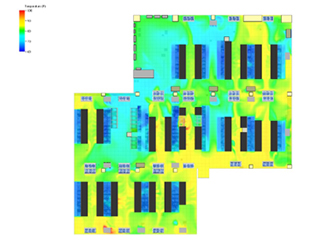

Datacenter cooling practices differ from one another. Planning starts from the layout, capacity, and equipment installed within the facility. In general, data center cooling is a complex process. There are thousands of servers and network devices omitting heat that needs to be managed. Scientific analysis such as Computational Fluid Dynamics (CFD) can be employed at the design stage to approximate the cooling capacity, airflow, and layout that should be implemented to cool down the data center.

Let us take an overlook to these methods.

Air-based Cooling

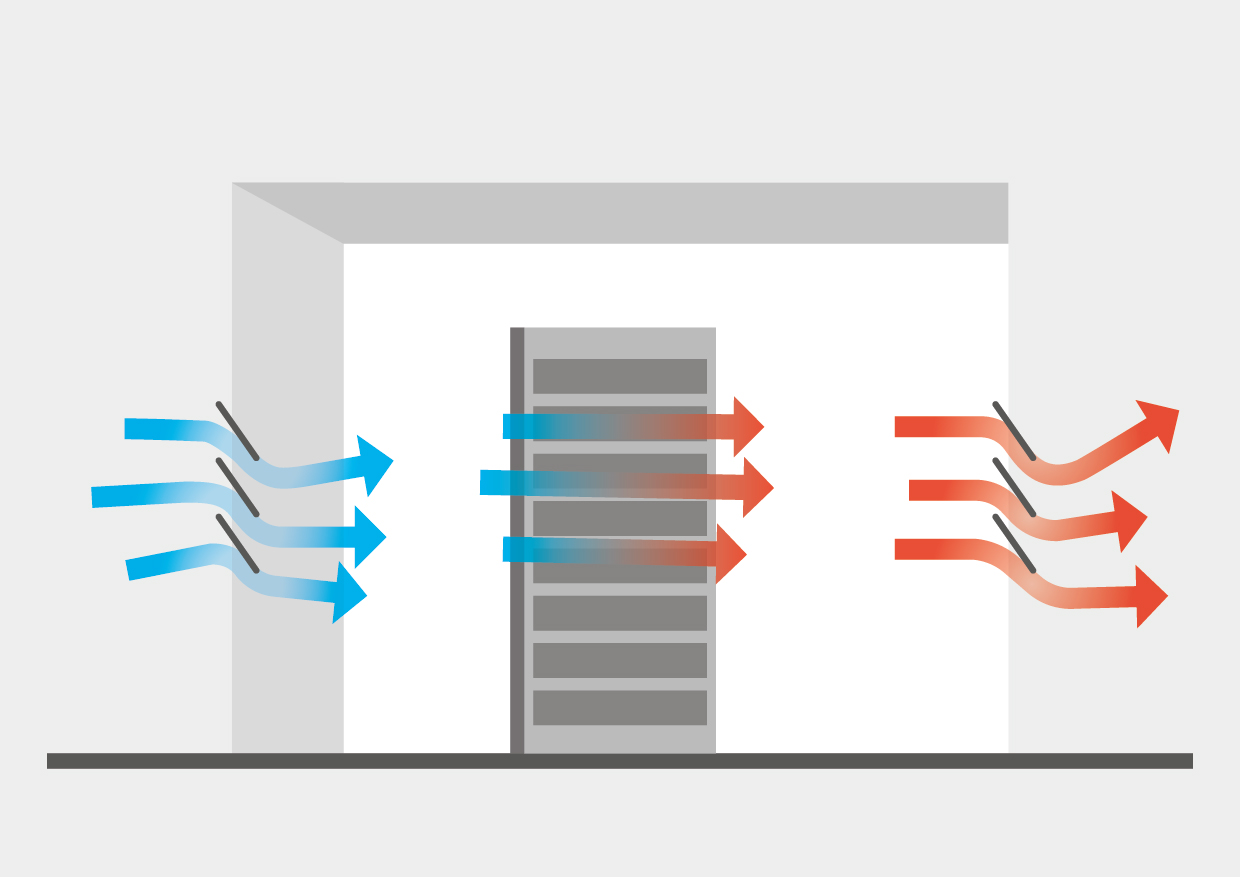

1. Cold Aisle / Hot Aisle

In this method, there is no containment of the hot and cold air. It is “Convection Mayhem”. Burning huge amounts of power on cooling is extremely inefficient.

This method is commonly found in small, private data centers or computer rooms with 1-6 racks. In this approach, the arrangement of racks is by facing the cold aisle to the hot aisle of the opposite row. What happens is that the cold and hot air fight with each other. The HVAC system is forced to work harder just so cold air can cover up all the hotspots found at the heavier-loaded racks.

The good news is that there’s a clear trend to move away from this inefficient and energy-consuming monster.

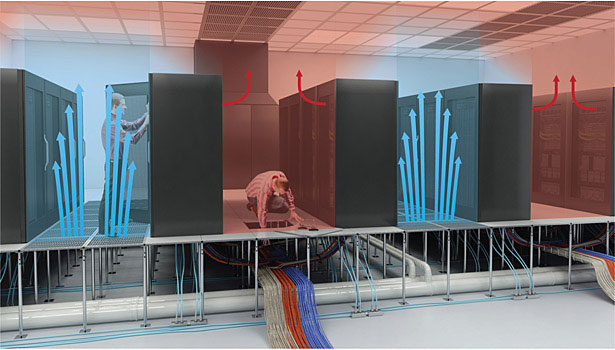

2. Cold or Hot Aisle Air Containment

Photo credit: www.esmagazine.com

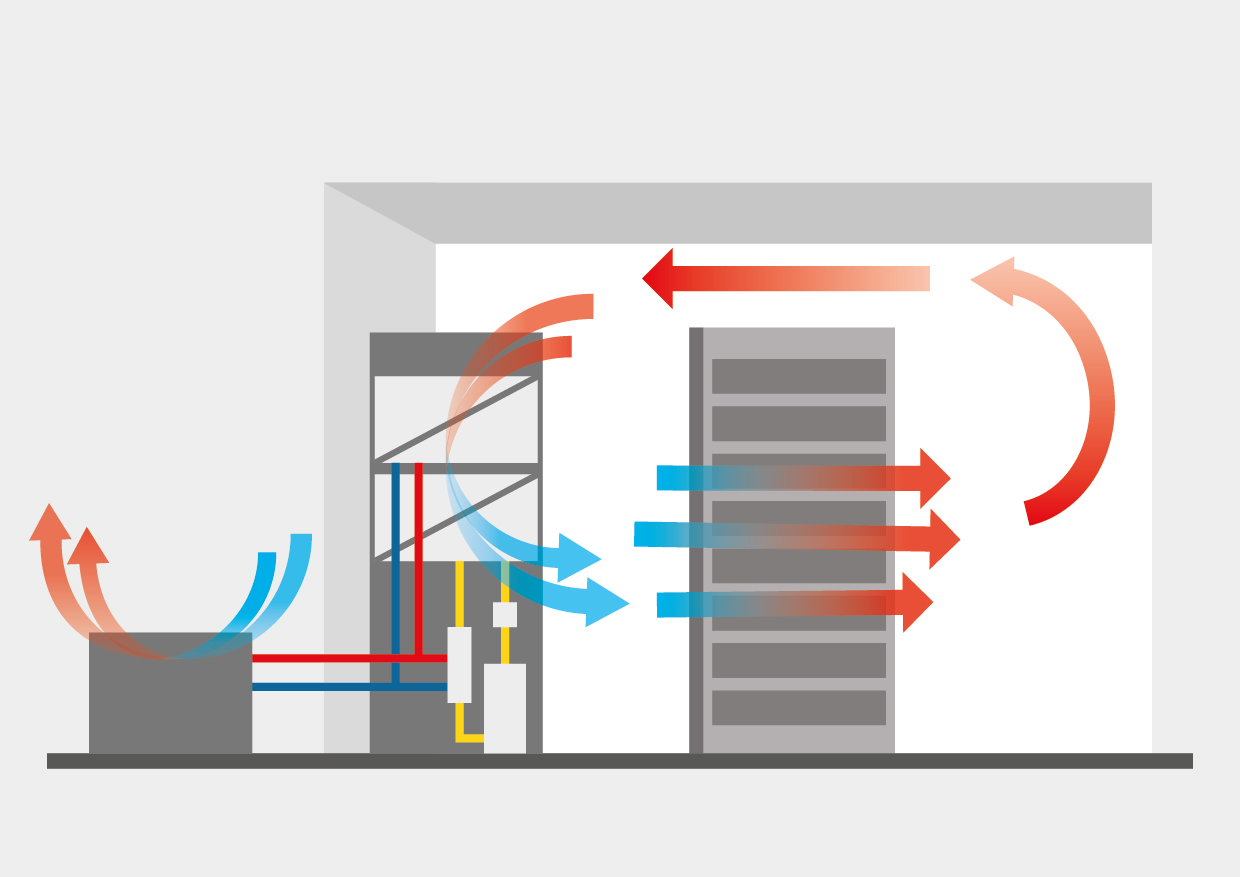

This method has been in the industry for a while already. It’s done by physically separating hot and cold air to avoid mixing. The air will then be directly processed to the Computer Room Air Conditioning unit (CRAC).

It works pretty well and substantially reduces the issues with “hot spots” and air mixing. But as efficient as this one is, operators still have to balance the pressure of plenums, so you wouldn’t waste energy cooling unnecessary areas. Cold air flows into the cold aisle through ductwork, overhead, or underfloor. Sometimes in the aisle chillers are used. This cold air is sucked into the servers, cooling them, and expelled to the room, where the hot air is returned to the CRAC. This prevention of air mixing allows for the efficient use of cooling power. Energy is not wasted, as all the cold air coming out the CRAC is sent to the servers rather than being warmed by the hot air mixing with it.

3. In-Rack Heat Extraction

The idea of this rack cooling method is pretty simple. Extract the heat inside the rack before it even reaches the server room. This is achieved by having the compressors and chillers in the rack to take the heat directly to the exterior of the data center.

The downhill of this method, however, is that it is costly to install on each rack. It doesn’t make sense for a facility with more than 1 or 2 racks.

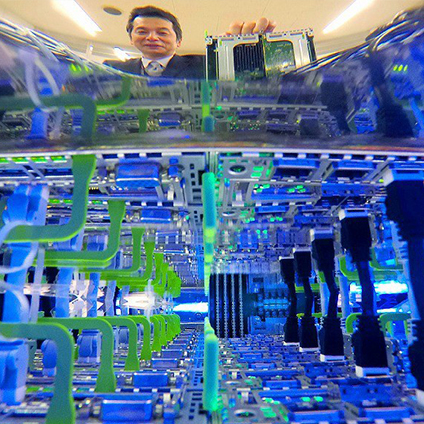

Liquid Immersion Cooling

Photo credit: www.fujitsu.com

This method is one of the revolutionary methods of data center cooling. It is the use of dielectric coolant fluid to gather the heat of the server components. Dielectric fluid can be used directly to electrical components such as CPUs, drives, memory, etc.

Liquid coolant is a hundred times more efficient to run through a server’s hot components and take the heat away to a heat exchanger than massive Computer Room Air Conditioning.

Compared to others, only this data center cooling method can make unprecedented PUEs possible.

There are two types of Liquid Immersion Cooling:

1. Indirect Liquid Cooling

This coolant liquid is being used without the liquid entering or directly contacting server components.

This method is less efficient as there is no direct contact and makes no effect at all.

2. Direct Liquid Cooling

This data center cooling method is where the coolant liquid is put in direct contact with the servers’ components. Under this category, there are two sub-techniques:

- Single-Phase- Open bath immersion liquid cooling: the coolant liquid never changes state.

- Semi-Open Immersion Liquid Cooling- The coolant liquid changes state from liquid to gas and back in a constant loop.

Free Cooling Methods

Direct Free Cooling

Photo Credit: www.stulz.de

Indirect Free Cooling

Photo Credit: www.stulz.de

This free cooling method keeps the windows shut. Outside air can not cause havoc inside the data center. This cooling may not be as complex as direct free cooling, however, this one is less efficient. In this data center cooling method, there is always at least one heat transfer.

Some Tips in Data Center Cooling Practices

The cooling unit placement and the distribution of air dictate how efficient a data center is. Here are some tips in data center cooling

- Consider all the options on what suits your data center best when deciding the airflow architecture. ( in-floor, in-row, overhead, and hybrid solutions)

- Ensure that the chosen one will optimize the airflow by analyzing and configuring it with computational fluid dynamics (CFD).

- Use Hot and cold aisle design strategy to provide good separation between air supply and return paths.

- Optimization of the overall energy efficiency of your data center cooling solution can be done with fans, fan motors, and variable frequency drives (VFD)

- Be energy efficient by following ASHRAE recommended supply air temperature guidelines.

- Choose a modular or scalable solution like AKCP Monitoring Solutions to allow your data center cooling infrastructure to support the increased loads due to growth.

AKCP Monitoring Solution

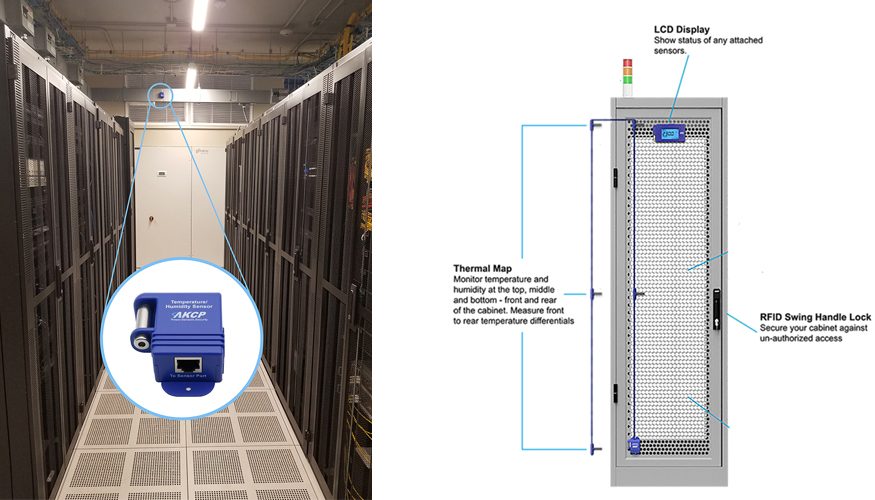

Cabinet Analysis Sensor

Airflow and Thermal Mapping for IT Cabinets

The Cabinet Analysis Sensor (CAS) features a cabinet thermal map for detecting hot spots and a differential pressure sensor for analysis of airflow. Monitor up to 16 cabinets from a single IP address with the sensorProbeX+ base units.

Differential Temperature (△T)

Cabinet thermal maps consist of 2 strings of 3x Temp and 1x Hum sensor. Monitor the temperature at the front and rear of the cabinet, top, middle, and bottom. The △T value, front to rear temperature differential is calculated and displayed with animated arrows in AKCPro Server cabinet rack map views.

Differential Pressure (△P)

There should always be a positive pressure at the front of the cabinet, to ensure that air from hot and cold aisles is not mixing. Air travels from areas of high pressure to low pressure, it is imperative for efficient cooling to check that there is higher pressure at the front of the cabinet and lower pressure at the rear.

Rack Maps and Containment Views

With an L-DCIM or PC with AKCPro Server installed, dedicated rack maps displaying Cabinet Analysis Sensor data can be configured to give a visual representation of each rack in your data center. If you are running a hot/cold aisle containment, then containment views can also be configured to give a sectional view of your racks and containment aisles.

Room and Rack Temperature Monitoring

AKCP Airflow and Wireless Air Differential Sensor